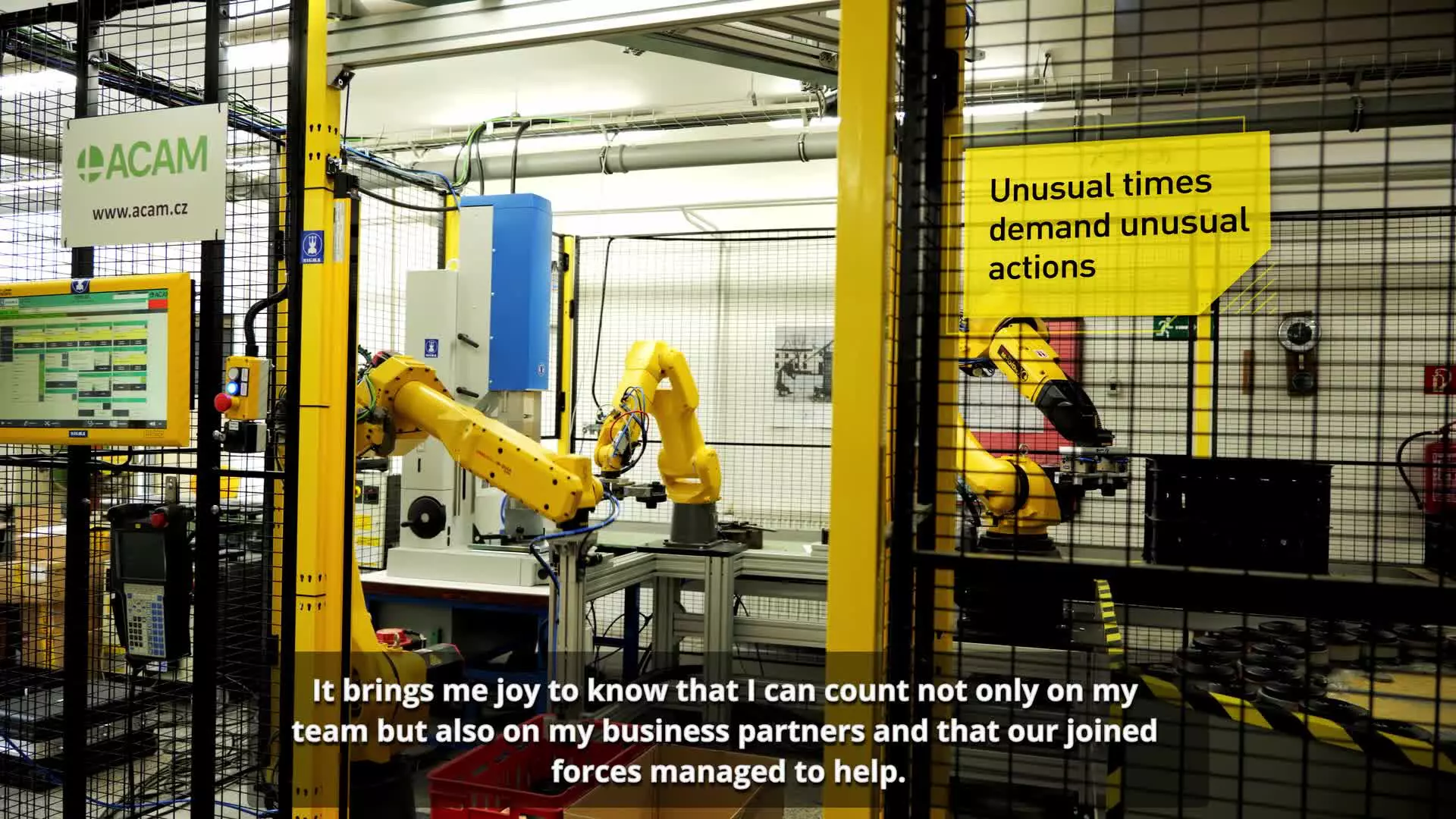

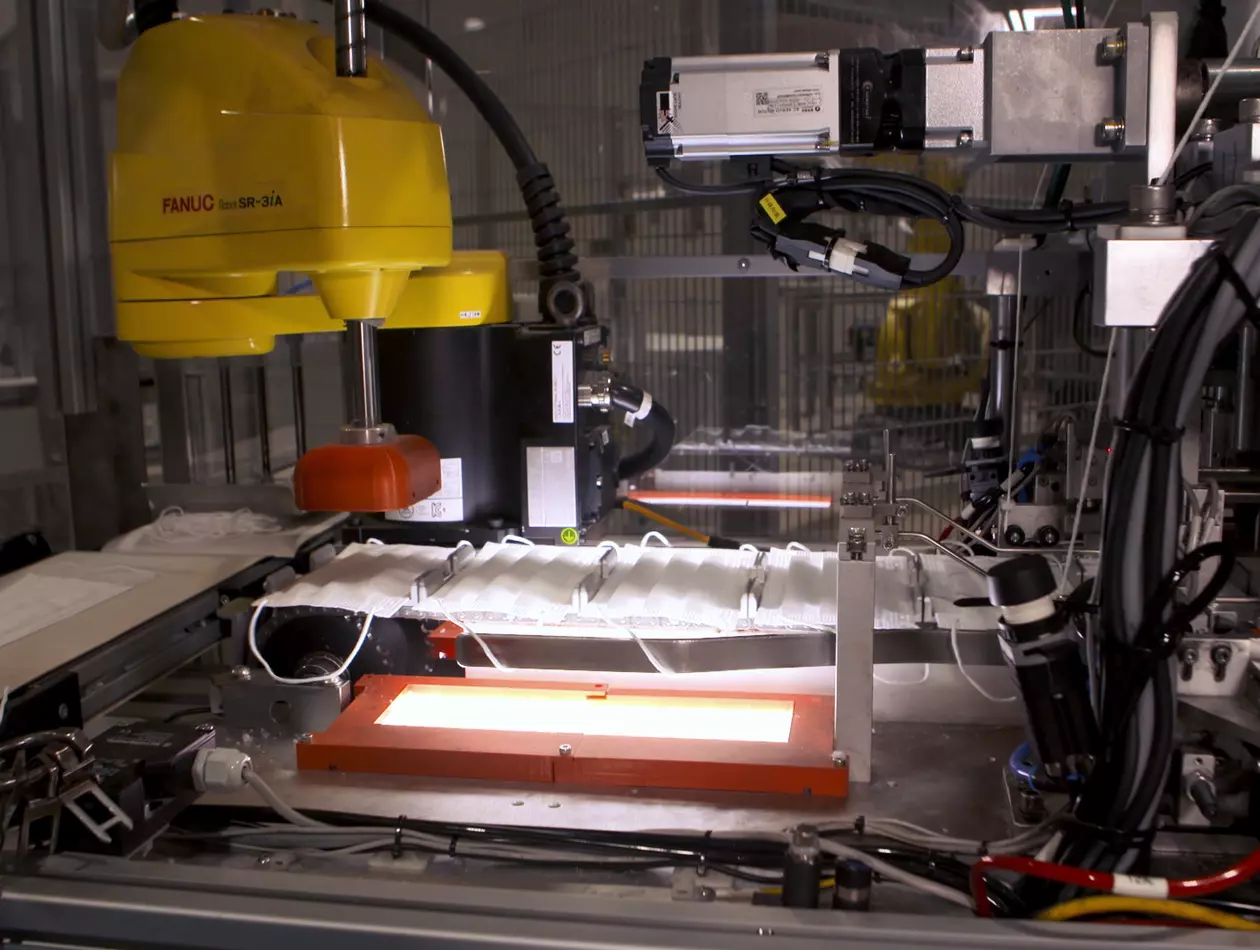

Robot Cell Established at Filter Manufacturer in Just 14 Days

Get Inspired

A FANUC robotok segítenek a maszkgyártónak szembenézni a kihívásokkal

Amikor a termelési kereslet rövid időn belül drámaian megnő, a robotok és az automatizálás sokkal gyorsabban segíthetnek a követelmények kielégítésében, mint azt sokan gondolnák. Ez az eredmény azonban nagyban függ a könnyen telepíthető, programozható és üzembe helyezhető robotok kiválasztásától.

A kozmetikai gyártó felismerte a FANUC automatizálás szépségét

A törökországi Erkul Cosmetics számos minőségi és hatékonysági előnyt élvez, amelyeket a különféle nagy teljesítményű FANUC automatizálási termékek biztosítanak. Ez a gyorsan növekvő kozmetikai vállalat a FANUC megoldásai által nyújtott versenyképességi előnyökkel támogatva meghatározó mércéül szolgál ágazatában.

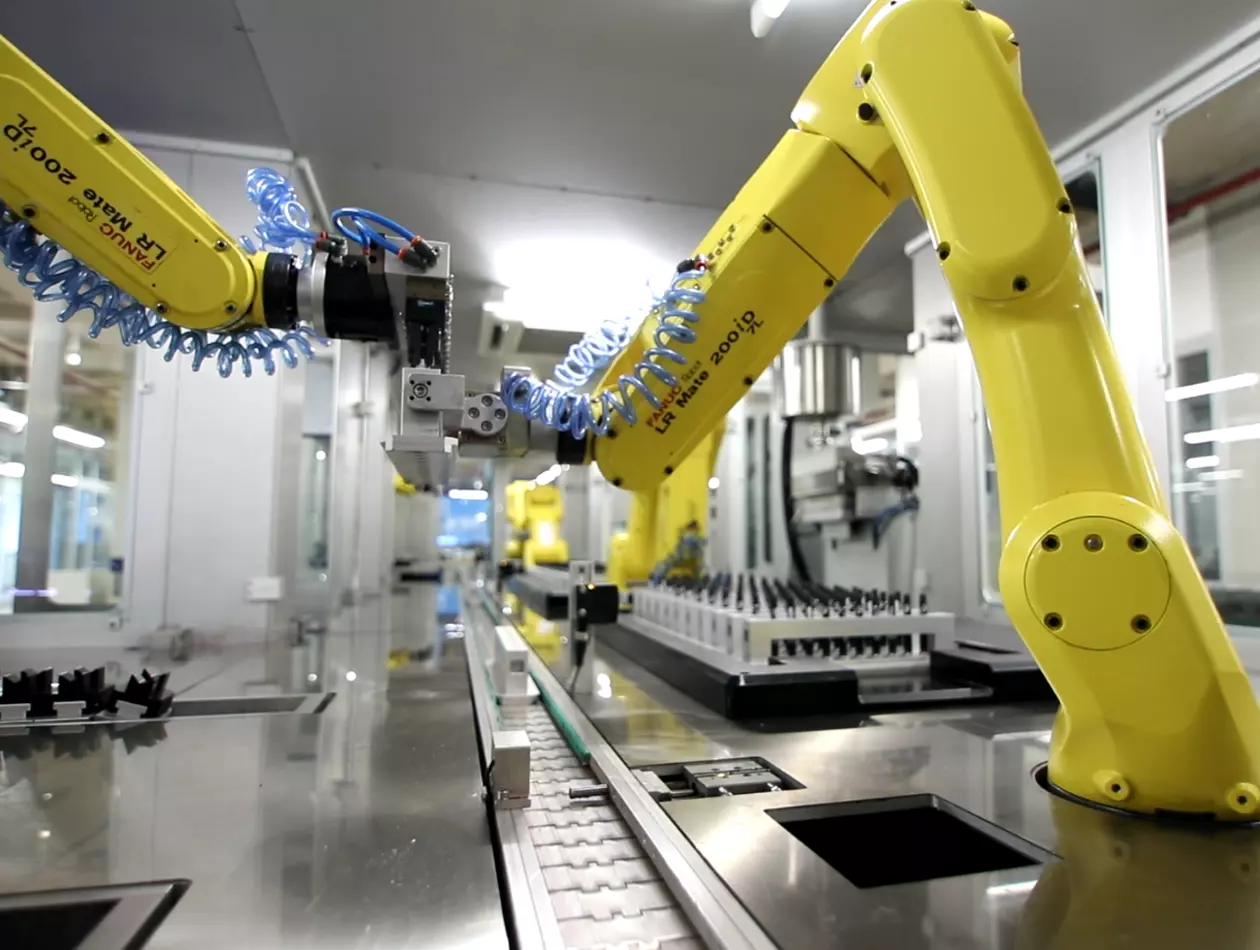

Fully Automated Assembly of Coffee Grinders

In the manufacture of popular household appliances such as coffee grinders, a number of prerequisites determine production success. For instance, only clearly structured, efficient and target-orientated processes will result in the required levels of production reliability. Achieving this ambition becomes significantly more realistic using automation, as market leader Eugster/Frismag AG can testify following its adoption of 14 FANUC LR Mate industrial robots and FANUC ZDT (Zero Down Time), which now enable the continuous automated assembly of a coffee grinder every 7 seconds.

FANUC Case Studies

Explore our comprehensive range of factory automation solutions, showcased in detailed case studies, and designed to optimise and streamline any manufacturing process.

Anyagmozgatás