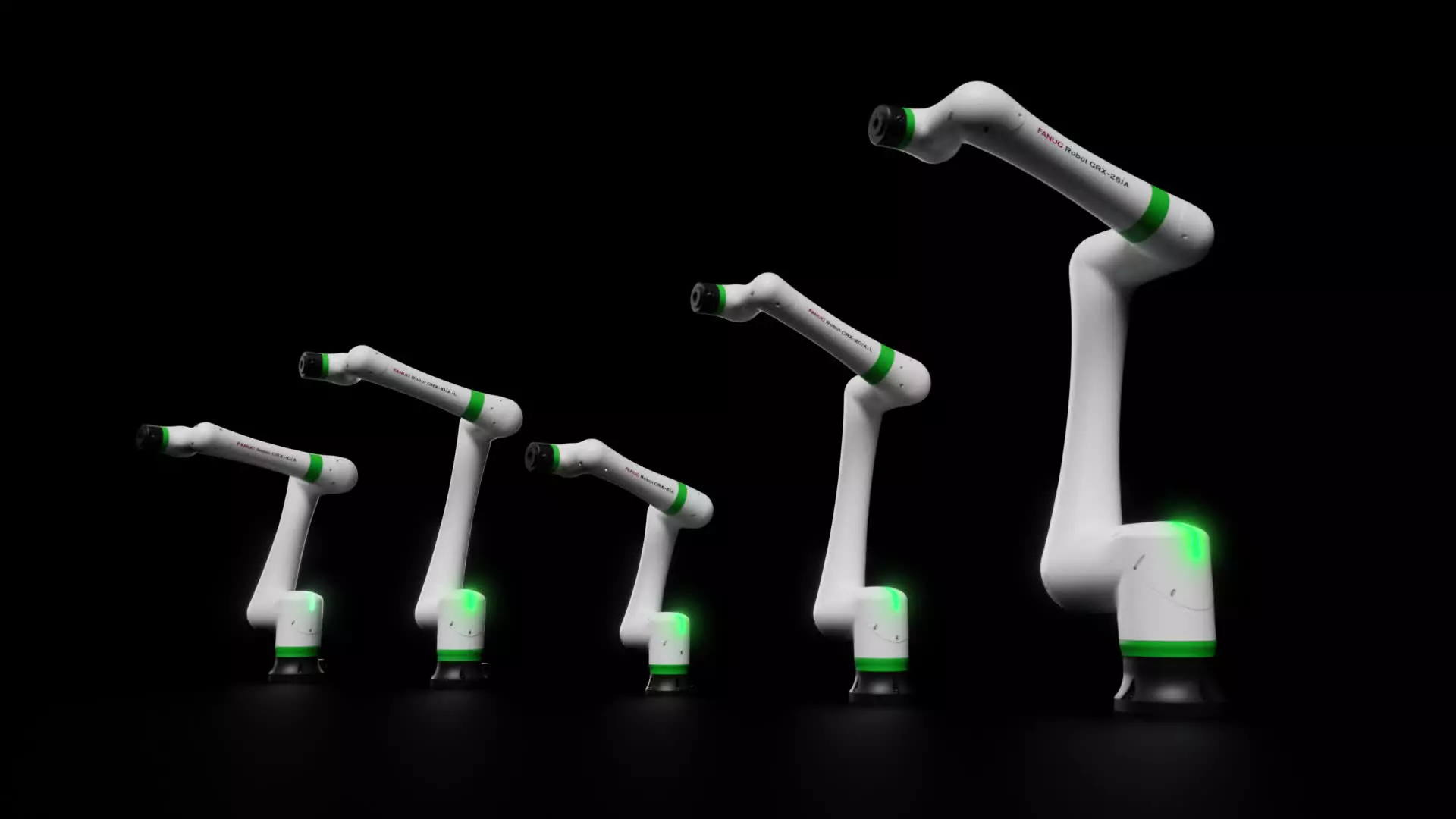

Robots colaborativos FANUC

Where There're Industrial Cobots, There's FANUC

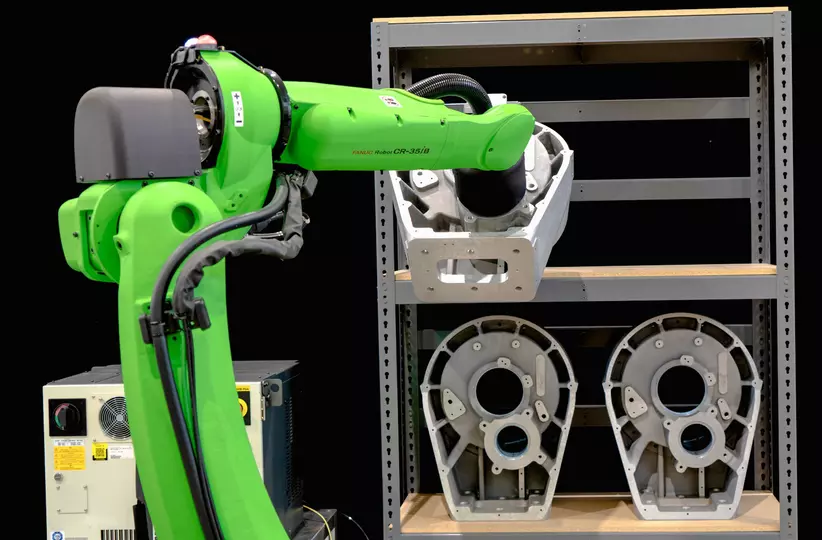

Cuando necesite un cobot industrial, no busque más allá de FANUC. Como líder mundial en la fabricación de cobot, ofrecemos una gran variedad de modelos de cobot de alta precisión capaces de manipular productos de hasta 50 kg de peso. Tanto si tiene experiencia con robots industriales tradicionales como si aún no ha trabajado con un brazo robótico, tenemos una solución de cobot que se adaptará a su entorno de producción. Tras 50 años en el sector de la robótica, conocemos los entornos de producción actuales, desde lotes pequeños y mezclas grandes hasta lotes grandes y mezclas pequeñas. Así que, cuando llegue el momento de considerar una aplicación de robot colaborativo, puede confiar en FANUC para ayudarle a entender la solución más eficiente y rentable.

Inspírese

Inspírese en el éxito de los demás

Uniendo fuerzas: El cobot de FANUC es la solución óptima para los adhesivos de AS

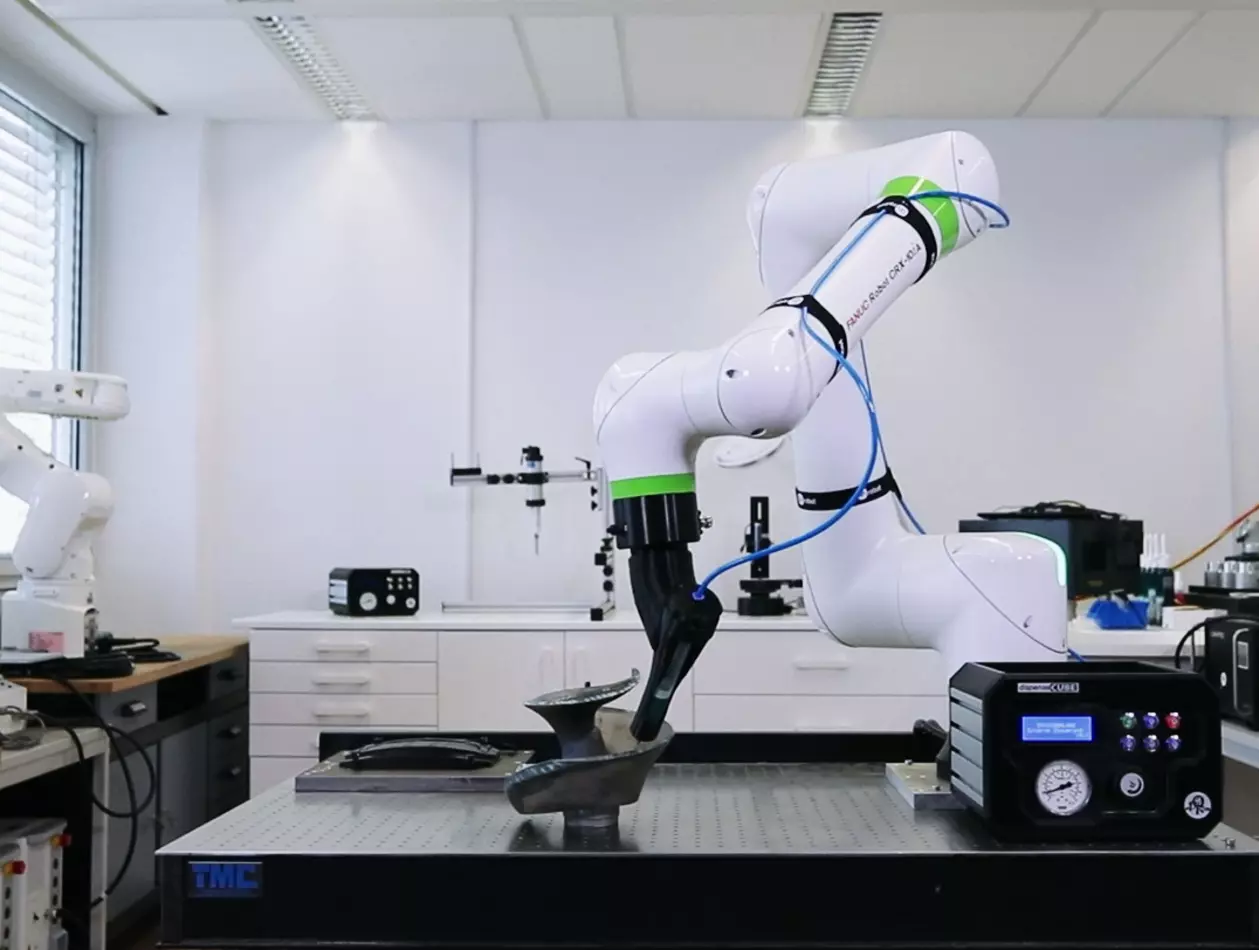

La automatización no es sólo para aplicaciones de gran volumen. AS Adhesive Solutions, consultora especializada y socio de la industria de adhesivos, reconoce que muchas PYMES que procesan pequeñas cantidades pueden beneficiarse de procesos total o parcialmente automatizados. En estos casos, un robot colaborativo (cobot) suele ser la mejor solución.

Cobot alivia el esfuerzo físico de los trabajadores

Los controles de calidad y el embalaje pueden ser físicamente exigentes. Sin embargo, la integración de robots colaborativos puede mejorar considerablemente la ergonomía de estas actividades.

FANUC Cobot Helps GER4TECH Make its Move

Developing a new robot requires expertise, experience and often collaboration with partners who have specialised knowledge in specific technology fields. So, when GER4TECH wanted a specialist in collaborative robots to bring advanced capabilities to its new autonomous mobile robot (AMR), the company reached out to FANUC.

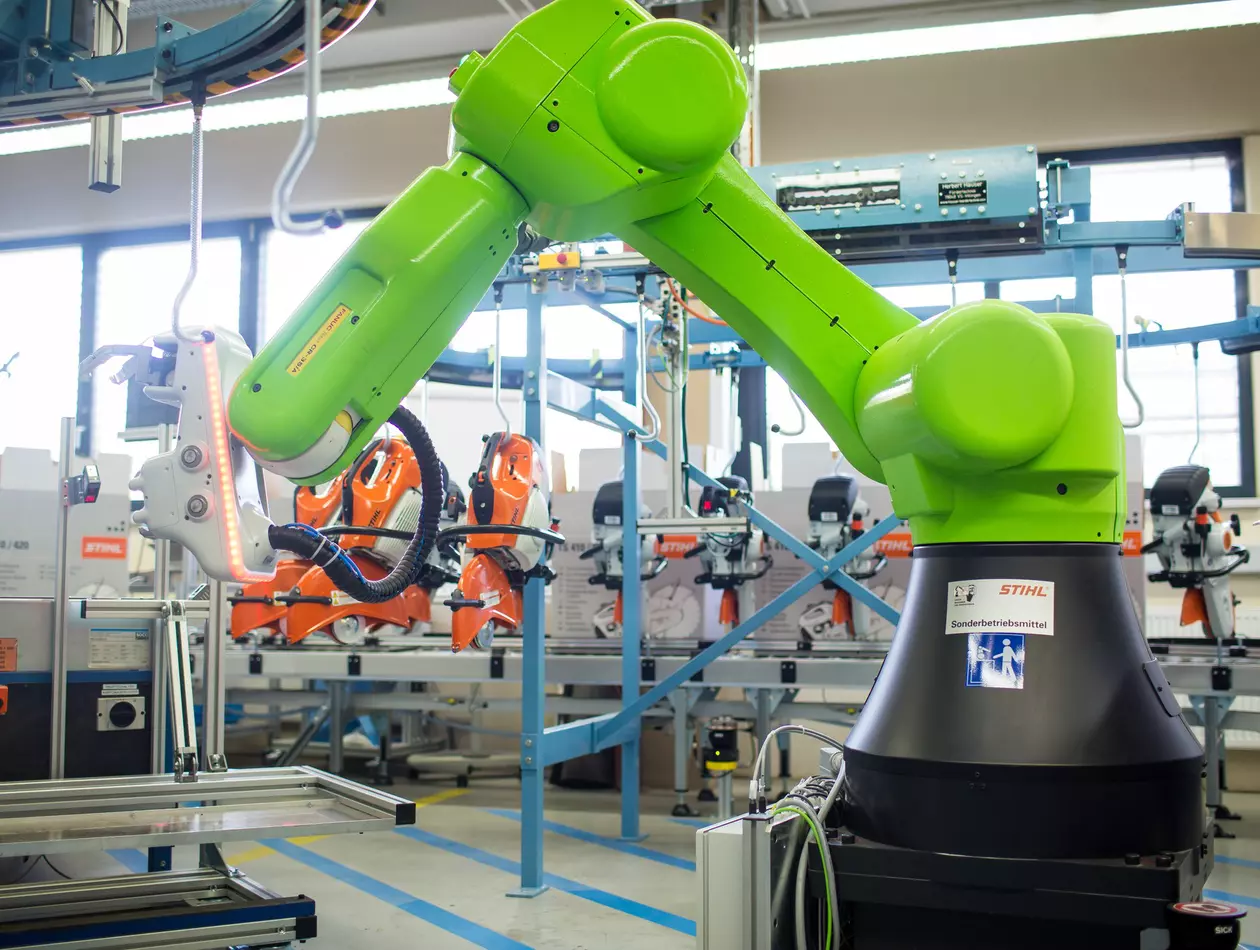

FANUC's CRX Cobot Boosts Production Flexibility

Bonvicini Carpenteria today enjoys even higher levels of quality and flexibility. The company can flex between automation solutions whenever production volumes dictate. In particular, Bonvicini Carpenteria is taking advantage of easy and fast robot programming with features such as drag and drop functionality and a simple tablet interface.

Ajuste perfecto para su aplicación

Soldadura por arco

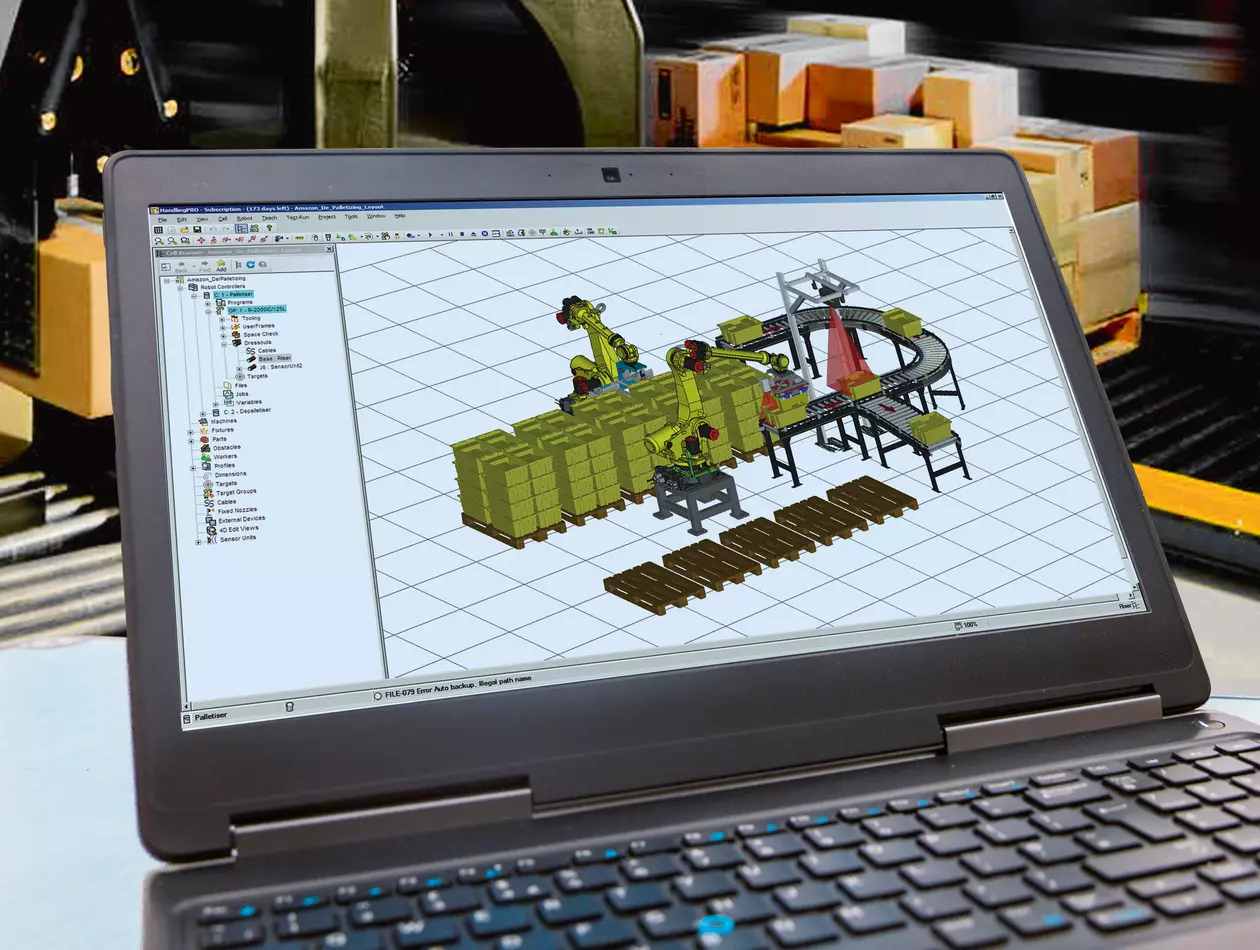

Paletizado

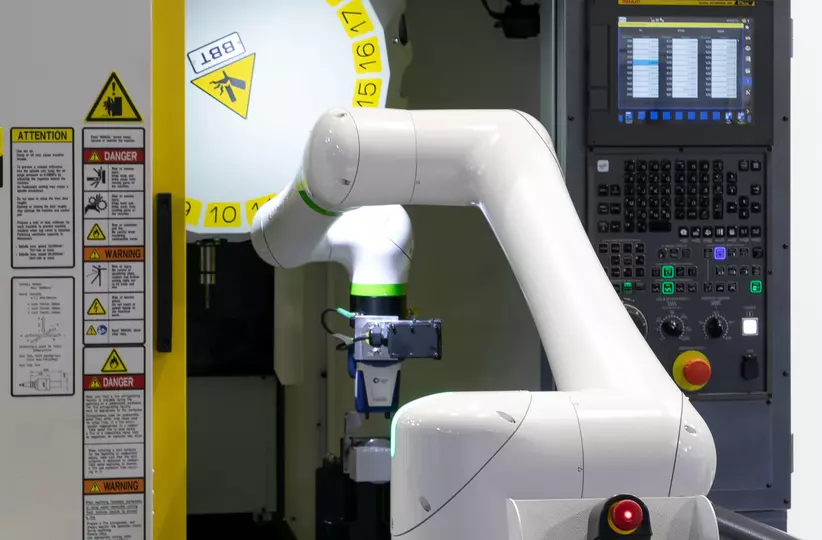

Alimentación de máquinas

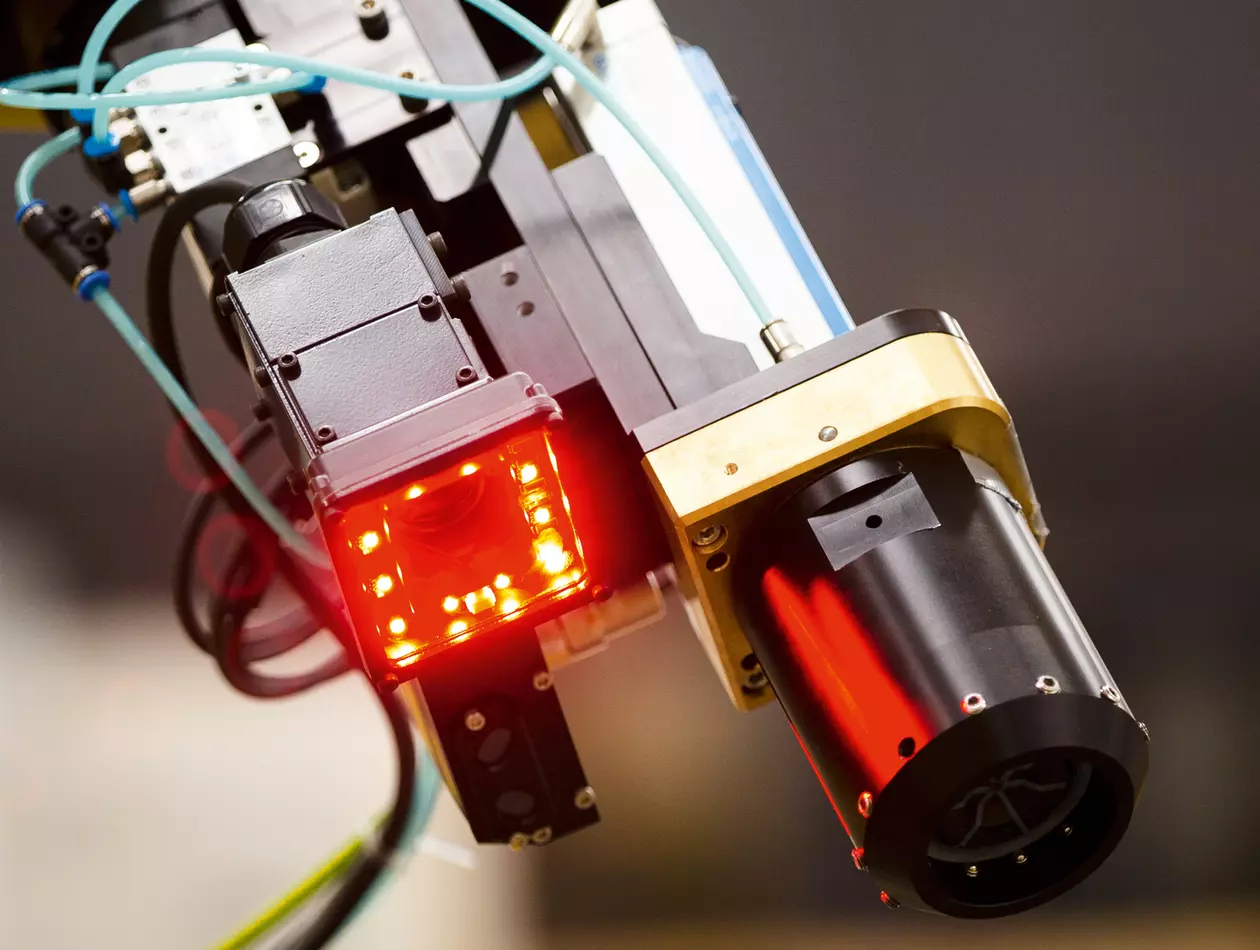

Inspección visual

Manipulación de materiales

Montaje

Soluciones a medida para su sector

Robótica y automatización para la industria del automóvil

Robótica y automatización para la industria aeroespacial

Vehículos eléctricos

Alimentación y bebidas

Electrónica