FANUC's CRX Cobot Boosts Production Flexibility

Get Inspired

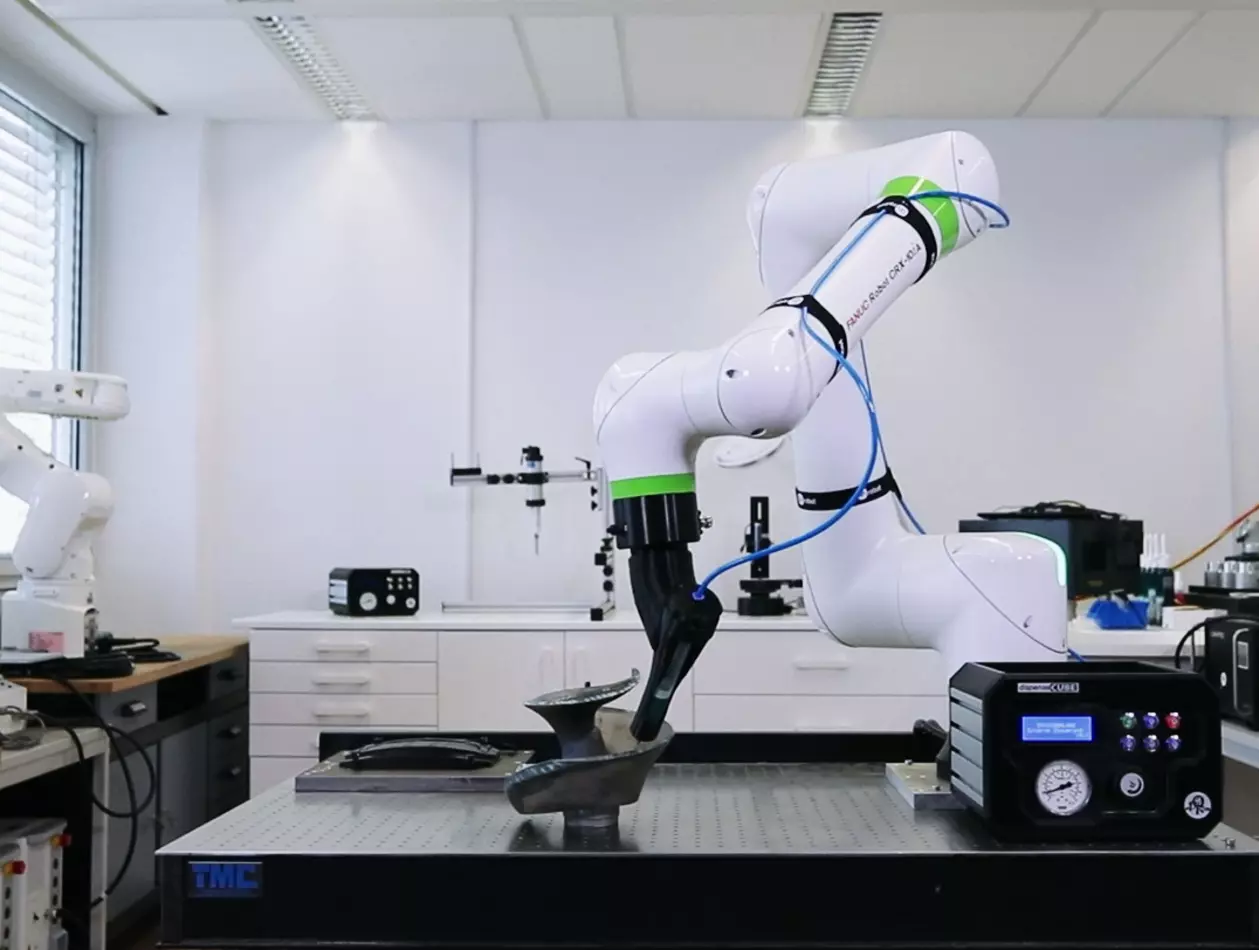

Spojení sil: FANUC Kobot je optimálním řešením pro AS Adhesive Solutions

Automatizace není určena pouze pro velkoobjemové aplikace. Společnost AS Adhesive Solutions, specializovaný poradce a partner pro průmysl lepidel, si uvědomuje, že mnoho malých a středních podniků, které zpracovávají malá množství, může mít prospěch z plně nebo částečně automatizovaných procesů. V takových případech představuje kolaborativní robot (kobot) často optimální řešení.

Zvedání těžkých břemen při konstrukci nákladních automobilů

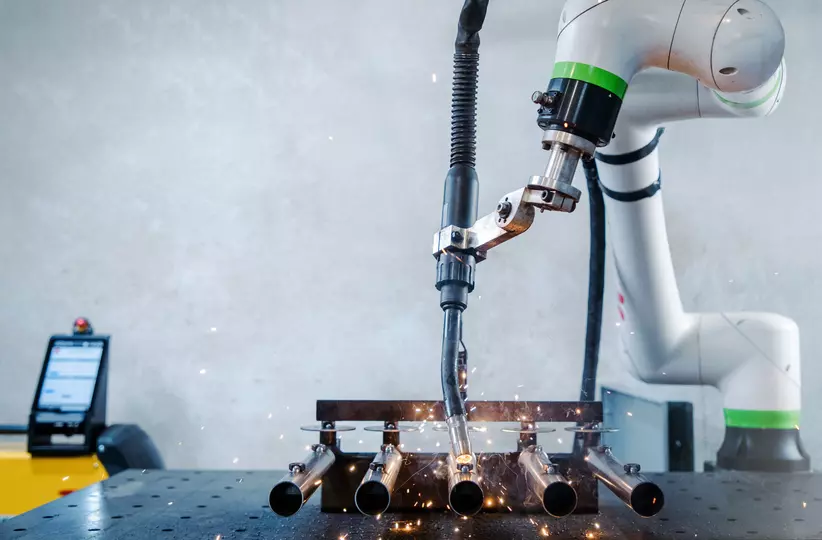

Společnost NTM mohla zvýšit výrobní kapacitu svých vozidel pro svoz odpadu tím, že se rozhodla automatizovat noční směnu. Díky použití výkoného robota, který dokáže zvednout až dvě tuny, a svařovacího robotického řešení může nyní finský závod společnosti pracovat bez obsluhy i v noci nebo o víkendech.

FANUC Case Studies

Explore our comprehensive range of factory automation solutions, showcased in detailed case studies, and designed to optimise and streamline any manufacturing process.

Obloukové svařování