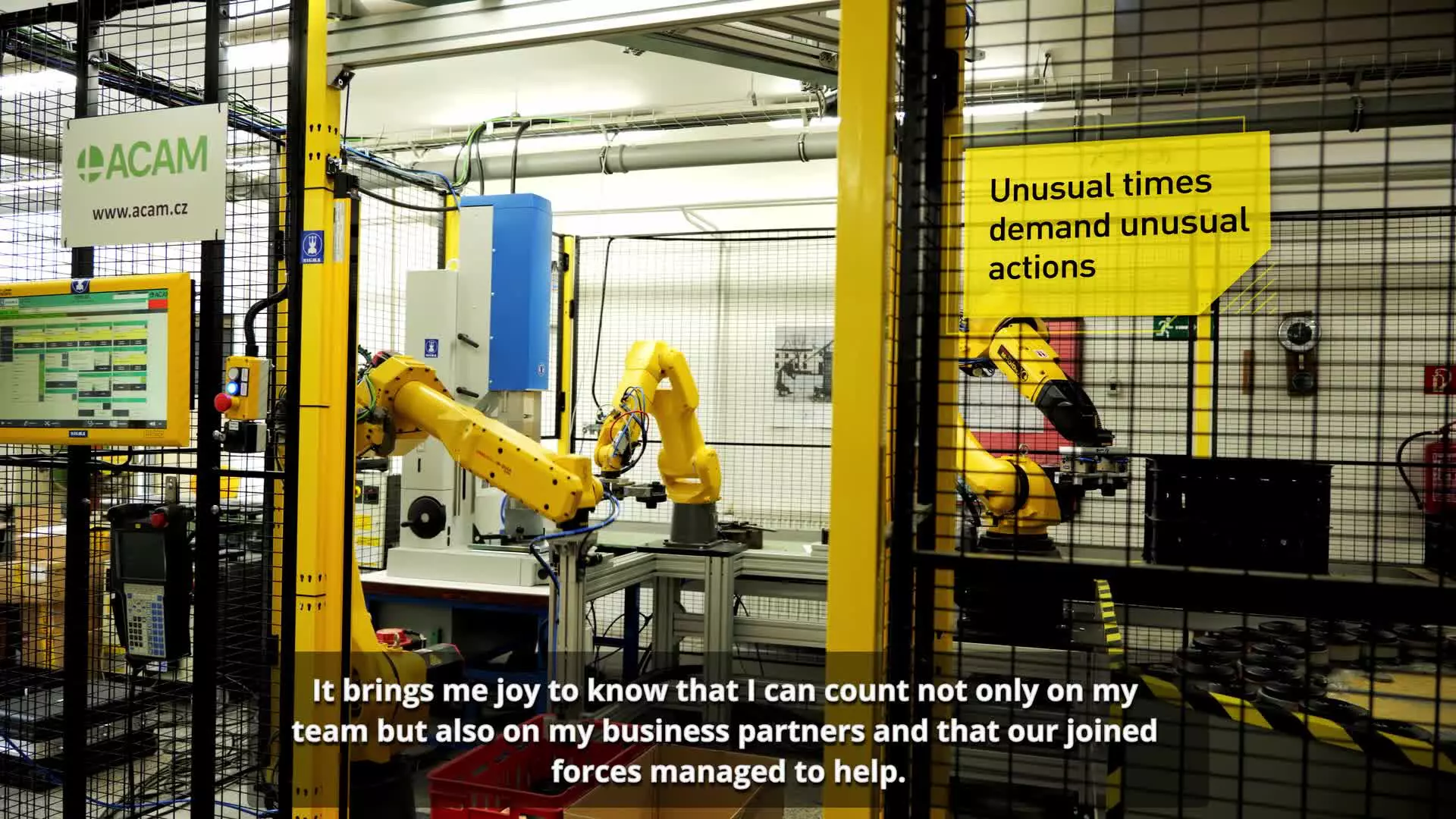

Robot Cell Established at Filter Manufacturer in Just 14 Days

Get Inspired

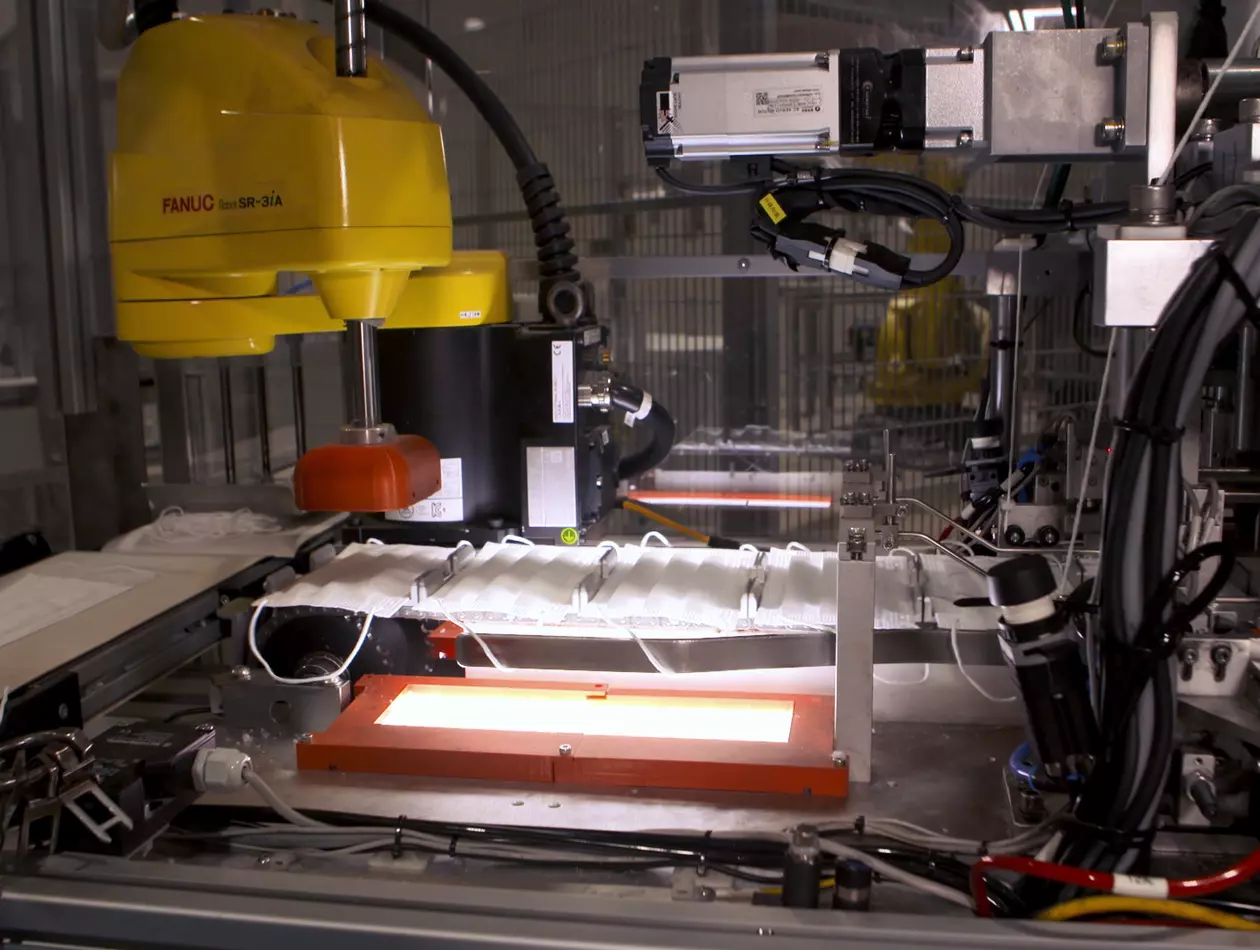

Los robots FANUC ayudan al fabricante de máscaras a afrontar el desafío

Cuando la demanda de producción se acelera drásticamente en un breve espacio de tiempo, los robots y la automatización pueden ayudar a satisfacer las necesidades mucho más rápido de lo que muchos creen. Sin embargo, este resultado depende en gran medida de la selección de robots que sean fáciles de instalar, programar y poner en marcha.

Un fabricante de cosméticos descubre la belleza de la automatización de FANUC

Erkul Cosmetics, en Turquía, se beneficia de un sinfín de ventajas de calidad y eficiencia proporcionadas por varios productos de automatización de alto Rendimiento de FANUC. Esta empresa de cosméticos de rápido crecimiento busca establecer un punto de referencia para la fabricación en su sector, con el apoyo de las ventajas competitivas que ofrecen las soluciones de FANUC.

Montaje totalmente automatizado de molinillos de café

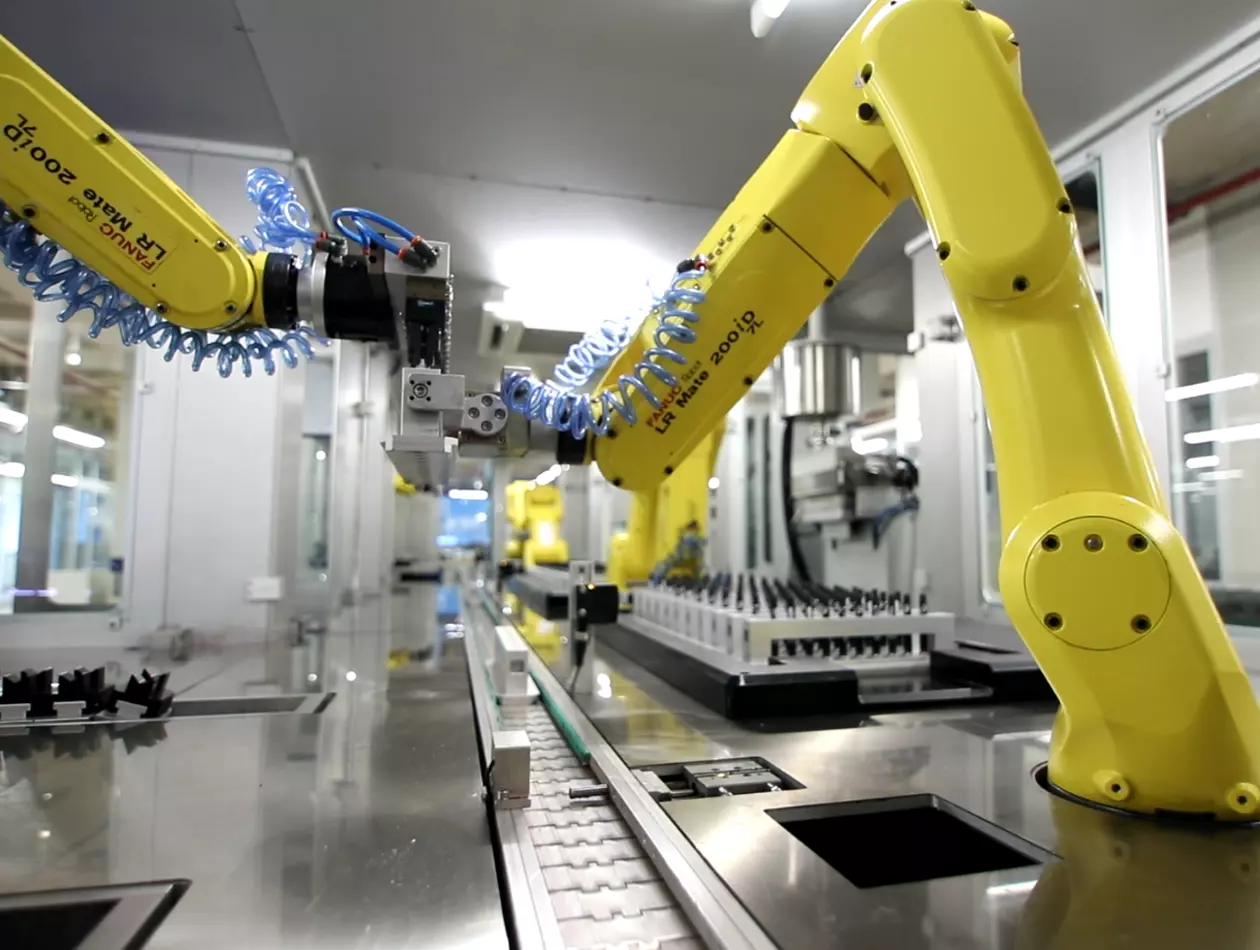

En la fabricación de electrodomésticos tan populares como los molinillos de café, una serie de requisitos previos determinan el éxito de la producción. Por ejemplo, sólo unos procesos claramente estructurados, eficientes y orientados a los objetivos permitirán alcanzar los niveles necesarios de fiabilidad en la producción. Alcanzar este objetivo es mucho más realista gracias a la automatización, como puede atestiguar el líder del mercado Eugster/Frismag AG tras la adopción de 14 robots industriales FANUC LR Mate y FANUC ZDT (Zero Down Time), que ahora permiten el montaje automatizado continuo de un molinillo de café cada 7 segundos.

FANUC Case Studies

Explore our comprehensive range of factory automation solutions, showcased in detailed case studies, and designed to optimise and streamline any manufacturing process.

Manipulación de materiales