Placing Plastic Injection-Moulding into Packing Trays

Get Inspired

Roboty v mliekarenskej výrobe

Preberanie úloh s dopytom po paletizácii je pre roboty hračkou. V prípade komplexných aplikácií dobre premyslený vývoj a dizajn zabezpečujú efektívnosť výroby a konkurencieschopnosť.

Výrobca kozmetiky vidí krásu automatizácie FANUC

Spoločnosť Erkul Cosmetics v Turecku využíva nespočetné množstvo výhod v oblasti kvality a efektívnosti, ktoré poskytujú rôzne vysoko výkonné automatizačné produkty FANUC. Tento rýchlo rastúci kozmetický podnik sa snaží stanoviť štandardy pre výrobu vo svojom odvetví, pričom ho podporujú konkurenčné výhody, ktoré poskytujú riešenia FANUC.

Robot FANUC sa venuje poľnohospodárstvu

Zdvíhanie ťažkých bremien a fyzická záťaž sú v Zelených službách už len vzdialenou spomienkou. Automatizovaný paletizačný systém s paletizačným robotom FANUC dnes zabezpečuje bezpečnú a produktívnu prevádzku.

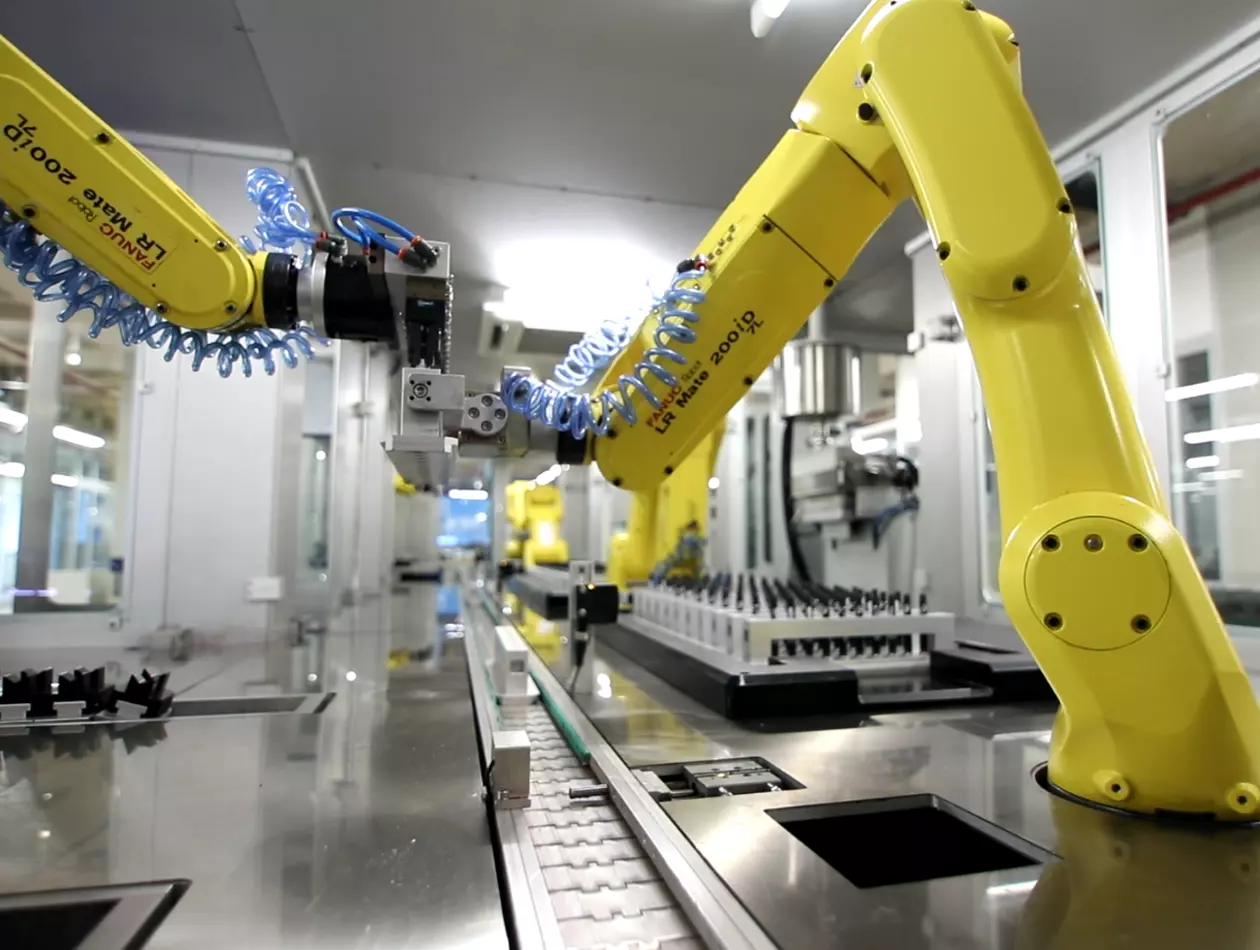

Plne automatizovaná montáž mlynčekov na kávu

Pri výrobe obľúbených domácich spotrebičov, ako sú mlynčeky na kávu, rozhoduje o úspechu výroby niekoľko predpokladov. Napríklad len jasne štruktúrované, efektívne a cieľovo orientované procesy vedú k požadovanej úrovni spoľahlivosti výroby. Dosiahnutie týchto ambícií sa stáva výrazne reálnejším pomocou automatizácie, čo môže potvrdiť líder na trhu Eugster/Frismag AG po nasadení 14 priemyselných robotov FANUC LR Mate a FANUC ZDT (Zero Down Time), ktoré teraz umožňujú nepretržitú automatizovanú montáž mlynčeka na kávu každých 7 sekúnd.

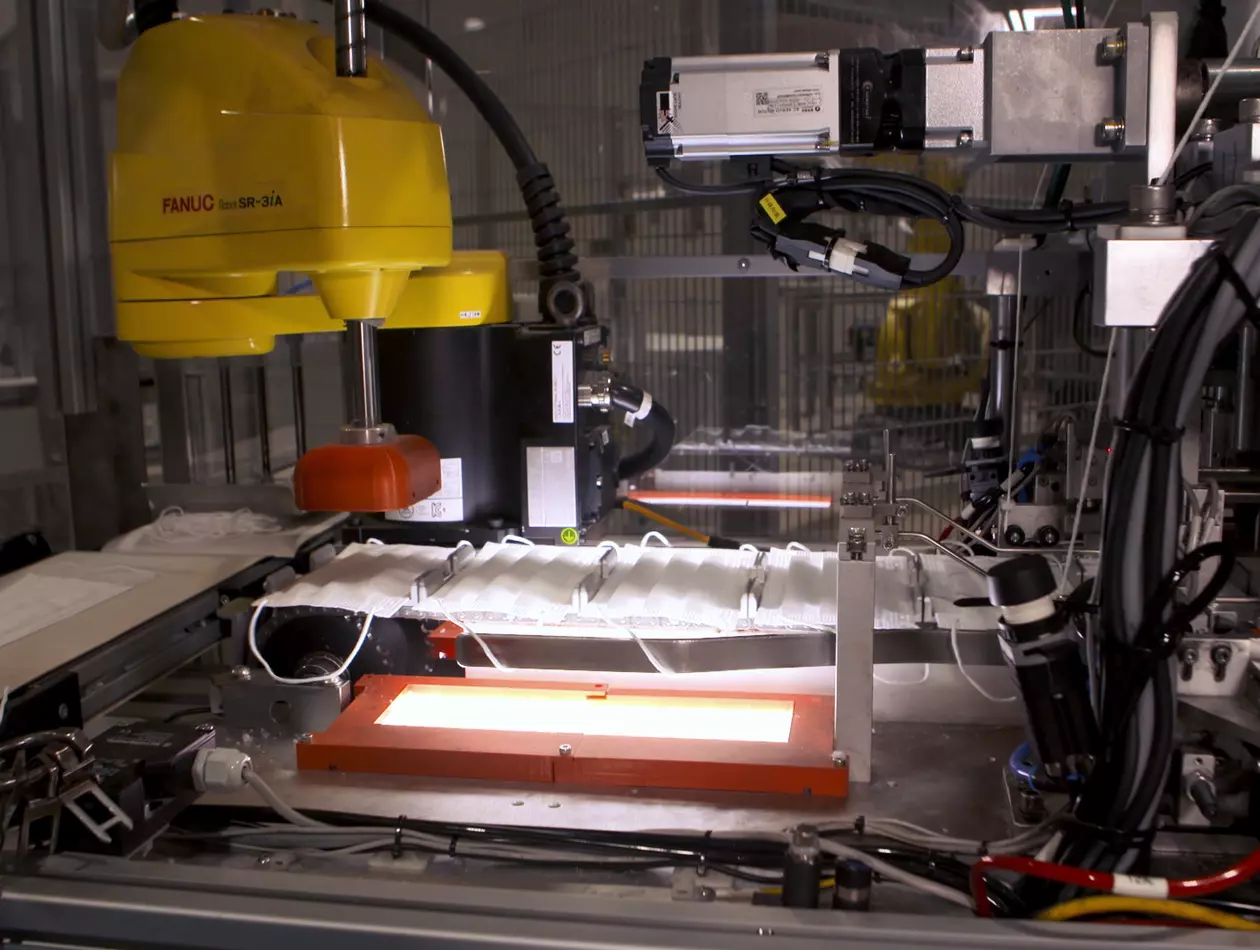

Roboty FANUC pomáhajú výrobcovi masiek čeliť výzve

Keď sa dopyt po výrobe v krátkom čase dramaticky zrýchli, roboty a automatizácia môžu pomôcť splniť požiadavky oveľa rýchlejšie, ako si mnohí uvedomujú. Tento výsledok však do veľkej miery závisí od výberu robotov, ktoré sa ľahko inštalujú, programujú a uvádzajú do prevádzky.

FANUC Case Studies

Explore our comprehensive range of factory automation solutions, showcased in detailed case studies, and designed to optimise and streamline any manufacturing process.

Obsluhovanie strojov