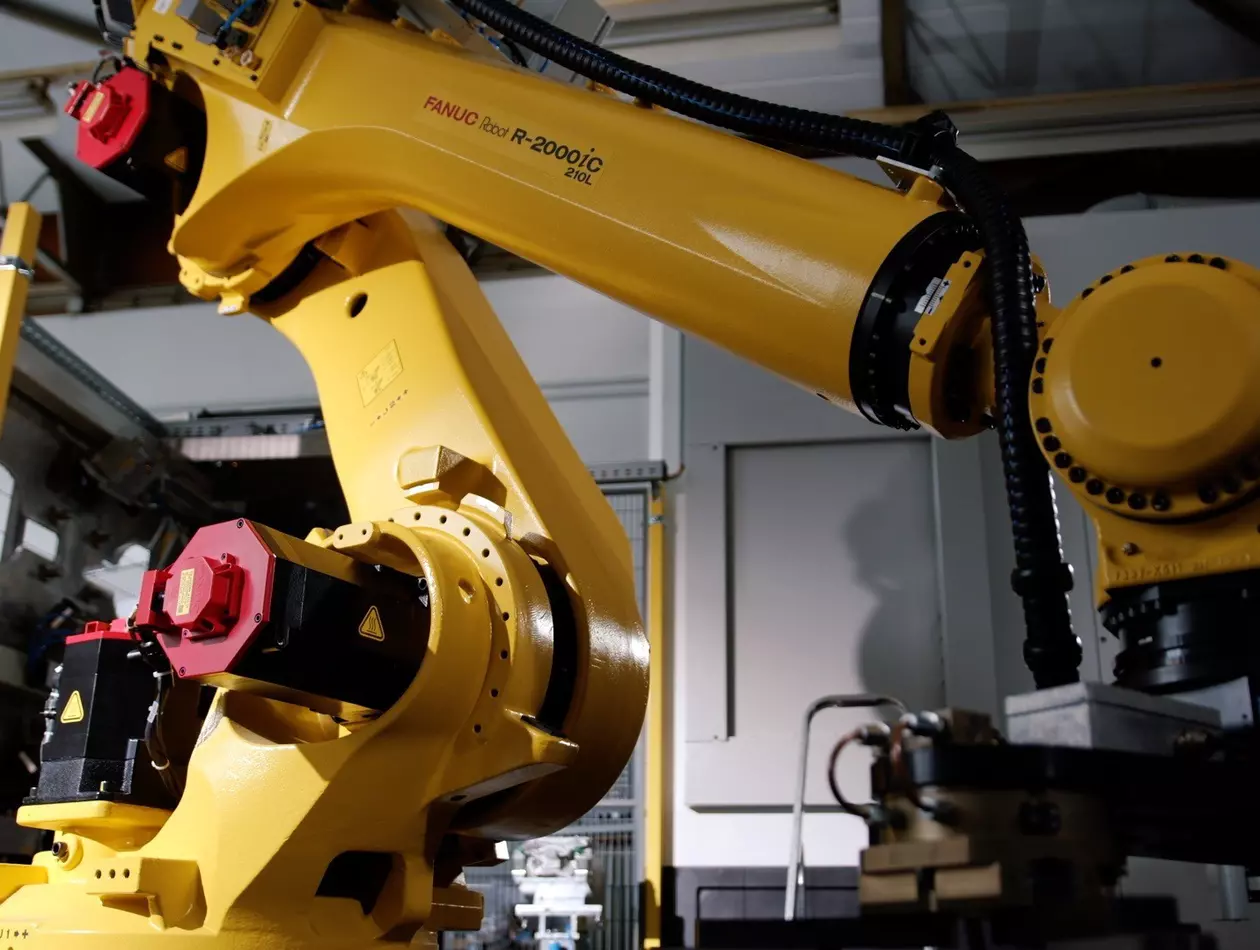

R-2000𝑖C/210L

Teilen Sie

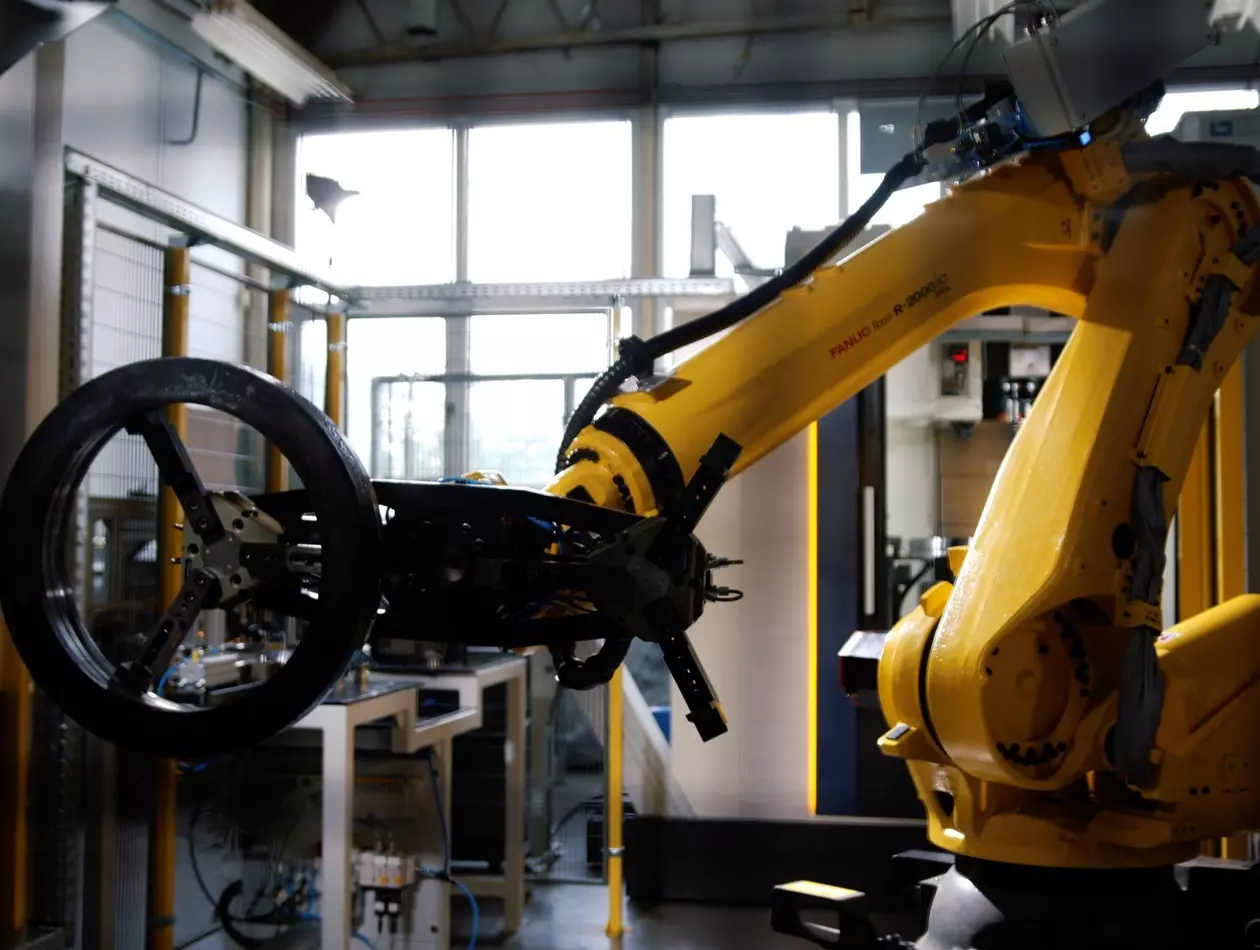

Der R-2000𝑖C/210L ist ein 6-achsiger Roboter mit außergewöhnlicher Steifigkeit und einer enormen Traglast von 210 kg. Mit einer verlängerten Reichweite von 3100 mm bietet dieser Roboter ultimative Flexibilität und ermöglicht einen effizienten Betrieb in einem breiten Spektrum von Anwendungen. Seine kompakte Stellfläche sorgt für eine effiziente Nutzung der Stellfläche und eignet sich daher perfekt für Anwendungen in der Automobilindustrie, wie z. B. Punktschweißen.

Roboter Nutzlast

210 kg

Roboter Reichweite

3100 mm

Achsanzahl

6

Inspiriert werden

Lassen Sie sich vom Erfolg anderer inspirieren

SIMLOGIC

Roboter in der Molkereiproduktion

Anspruchsvolle Aufgaben der Palettierung sind für Roboter ein Kinderspiel. Bei komplexen Anwendungen sorgen eine durchdachte Entwicklung und Konstruktion für Produktionseffizienz und Wettbewerbsfähigkeit.

Mikron Plus

Automatisierung der Bearbeitung von großen ringförmigen Lagern mit Robotern

Für die Bearbeitung großer ringförmiger Lager wurde eine Roboterzelle eingerichtet. Ein FANUC R-2000𝑖C/210L-Roboter mit einer Tragfähigkeit von 210 kg und 3D Vision Sensor be- und entlädt Ringe in eine vertikale CNC-Drehmaschine. Mikron Plus setzte die CNC Servo Learning Oscillation von FANUC ein, um lange Späne in kleinere Stücke zu zerlegen. Diese Lösung steigerte die Produktivität, senkte die Kosten und gewährleistete hohe Genauigkeit und Qualität bei gleichzeitiger Minimierung der Abhängigkeit von Arbeitskräften.

Perfekte Passform für Ihre Anwendung

Materialhandhabung

Automatisieren Sie die Materialhandhabung mit Industrierobotern, um zahlreiche Vorteile für Ihr Unternehmen zu erschließen. Steigern Sie die Effizienz und Produktivität erheblich, indem Sie den Zeit- und Arbeitsaufwand für die manuelle Handhabung reduzieren. Lassen Sie die Roboter kontinuierlich und ermüdungsfrei arbeiten, um eine gleichbleibende Leistung zu gewährleisten und Fehler zu minimieren, was zu einem höheren Durchsatz und schnelleren Bearbeitungszeiten führt.

Punktschweißen

Sorgen Sie mit Punktschweißrobotern für hochwertige Schweißnähte und steigern Sie Ihre Produktivität. Integrieren Sie sie als wesentliche Komponente in moderne Fertigungsprozesse, um eine zuverlässige und gleichbleibende Leistung zu gewährleisten. Sorgen Sie für eine gleichbleibende Qualität der Schweißnähte, reduzieren Sie die Produktionszeit und minimieren Sie menschliche Fehler. Senken Sie die Arbeitskosten, verringern Sie den Materialabfall und ermöglichen Sie einen 24/7-Betrieb, um die Gesamteffizienz der Fertigung zu steigern.

Maßgeschneiderte Lösungen für Ihre Branche

Robotik und Automatisierung für die Luft- und Raumfahrtindustrie

Die fortschrittliche Robotik von FANUC: Optimierung der Fertigungsprozesse in der Luft- und Raumfahrt.

Robotik und Automatisierung für die Automobilindustrie

Spitzenleistungen in der Automobilindustrie: Die vielseitigen Automatisierungslösungen von FANUC.

Elektrisch betriebene Fahrzeuge

Niemand hat mehr Erfahrung mit der Automatisierung der Produktion von Elektrofahrzeugen als FANUC. Vertrauen Sie darauf, dass wir Sie bei der Automatisierung aller Ihrer EV-Fertigungsprozesse unterstützen.

Elektronik

Wir bieten automatisierte Lösungen für die Elektronikfertigung und für Reinraumumgebungen.

Lebensmittel

Lebensmittel und Getränke sind unser tägliches Brot. Setzen Sie sich noch heute mit uns in Verbindung, um unsere Erfahrung mit Robotern in der Lebensmittel- und Getränkeindustrie für Sie zu nutzen.

Robotics & Automation for the Medical Industry

Enhancing medical industry efficiency through robotics and automation!

Lagerhaltung, Logistik, Post und Pakete

Das breite Angebot an FANUC Lagerrobotern erfüllt die Anforderungen aller, die ihr Lager, Distributionszentrum, Fulfillment Center und vieles mehr automatisieren möchten.