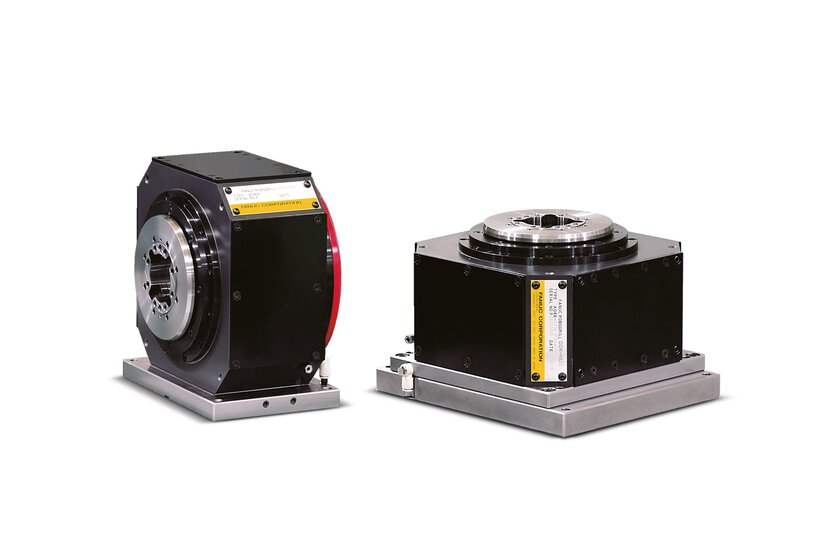

ROBODRILL 𝛼-D28L𝑖B5 ADV Plus Y500

Get Inspired

Get Inspiration from Other's Success

EUROEDIL Enjoys Faster Cutting Rates and Higher Throughput with FANUC Machines

With its new FANUC machines in-site, EUROEDIL has increased its cutting rate and throughput to meet rising volume demands from customers. Moreover, the accuracy and precision of the company’s die-cutting tools have improved noticeably.

FANUC Provides Vision of the Future at ZAP

While machining can benefit greatly from the adoption of a machine-tending robot, the addition of 3D cameras introduces an extra level of intelligence that leads to autonomous production and particular benefits for manufacturers.

Success of FANUC Robot Cell Leads to New Revenue Stream

What do most contract machining companies consider when looking to reach the next level of efficiency, productivity and reliability? The answer, of course, is automation. For this very reason, Germany-based WU Mechanische Werkstätte GmbH built an automation cell -featuring a FANUC industrial robot - for loading and unloading one of its own machine tools. Two years later, a visitor liked the concept so much he asked WU to build him one. This marked the beginning of an additional revenue stream based on the design and build of automation cells featuring high-performance industrial robots from FANUC.

Perfect Fit for Your Application

CNC Milling

5 Axis Machining

Tailored Solutions for Your Industry

Electronics

Complex Machining for the Aerospace Industry

Complex Machining for the Automotive Industry