/

Thermal Displacement Compensation Software Functions

Thermal Displacement Compensation Software Functions

Share

The ROBODRILL Series of machining centers, renowned for their precision and efficiency, come equipped with advanced features to ensure accurate and reliable machining results. Among these features, the Thermal Displacement Compensation software function plays a pivotal role in maintaining dimensional accuracy under varying thermal conditions. In this text, we will delve into the standard Thermal Displacement Compensation function and the optional AI Thermal Displacement Compensation II function, both of which contribute to enhancing the performance of ROBODRILL machining centers.

- Key Benefits

- Standard Function

- Optional Features

- Documents

Key Benefits

Benefits for Your Business

Enhanced Dimensional Accuracy

The standard Thermal Displacement Compensation function and optional AI Thermal Displacement Compensation II function continuously monitor and compensate for thermal displacements in real-time. This ensures that ROBODRILL machining centers maintain precise dimensional accuracy, even in fluctuating thermal conditions, resulting in high-quality machined parts.

Simplify Warm-Up Times

These functions simplify setup and reduce warm-up times by compensating for thermal displacements. This feature maximises production uptime, increases overall efficiency and energy efficiency.

Improved Productivity and Repeatability

By addressing the challenges posed by thermal displacement, these software functions enhance the repeatability of ROBODRILL machining centers. They allow for consistent, high-quality machining operations, ultimately boosting productivity and reducing the risk of errors.

Standard Function

Standard Thermal Displacement Compensation

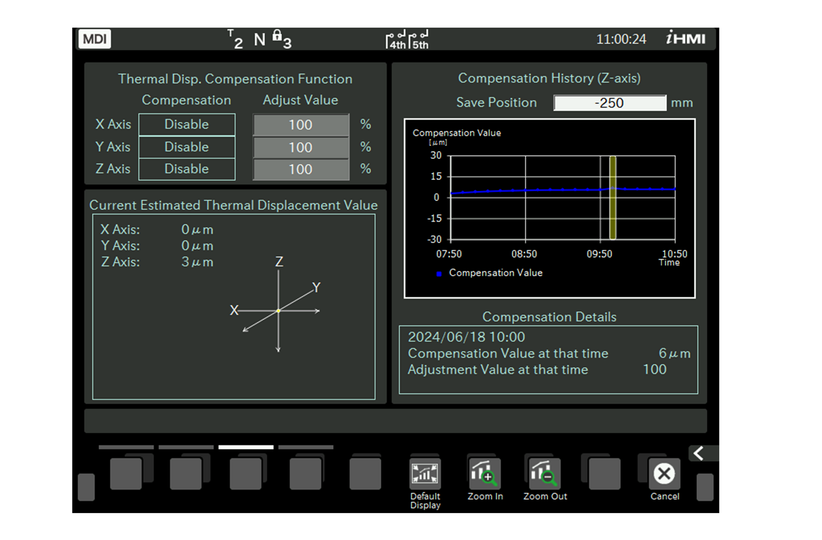

The standard Thermal Displacement Compensation function in ROBODRILL utilises the real-time monitoring of the spindle and feed axes to estimate and compensate for thermal displacements. This critical feature addresses the inherent challenge of temperature variations in machining centers, which can adversely affect machining precision.

Real-time Monitoring

The ROBODRILL constantly monitors the operational status of both the spindle and feed axis, ensuring accurate data collection regarding expected thermal variations.

Thermal Displacement Estimation

Using the collected data, the machine estimates the thermal displacement that occurs during operation, factoring in temperature changes based on predefined data.

Real-time Compensation

Once the thermal displacement is estimated, the ROBODRILL's software automatically adjusts its machining processes in real-time to counteract any dimensional deviations caused by thermal effects.

Optional Touch Probe Integration

For even greater precision, the ROBODRILL can be equipped with an optional touch probe. This accessory can automatically adjust the compensation effect based on real-time measurements, fine-tuning the machining process to maintain high accuracy.

Optional Features

AI Thermal Displacement Compensation II

The optional AI Thermal Displacement Compensation II function represents a significant advancement in thermal displacement compensation technology. This feature reduces machine warm-up times while enhancing machining accuracy in the presence of varying environmental temperature conditions.

Easy Setup

AI Thermal Displacement Compensation II is designed for ease of use, allowing operators to configure it quickly and efficiently.

Reduced Warm-Up Times

By continuously monitoring the actual temperature of machine's components, the function optimises warm-up times. This ensures that the machine can be employed in production before reaching full thermal stability after long warm-up.

Compensation for Thermal Displacement

As machining centers operate, temperature variations can lead to dimensional inaccuracies. AI Thermal Displacement Compensation II automatically adjusts the machining process to compensate for any displacement that occurs due to thermal effects, maintaining precise dimensional accuracy.

Documents

Download for Additional Information

Access essential technical specifications and valuable information about our products through our downloadable documents, aiding your decision-making process and maximising the utilisation of your FANUC products.

Get in Touch

Solutions

CUSTOMER SERVICE

NEWS & MEDIA

CONTACT