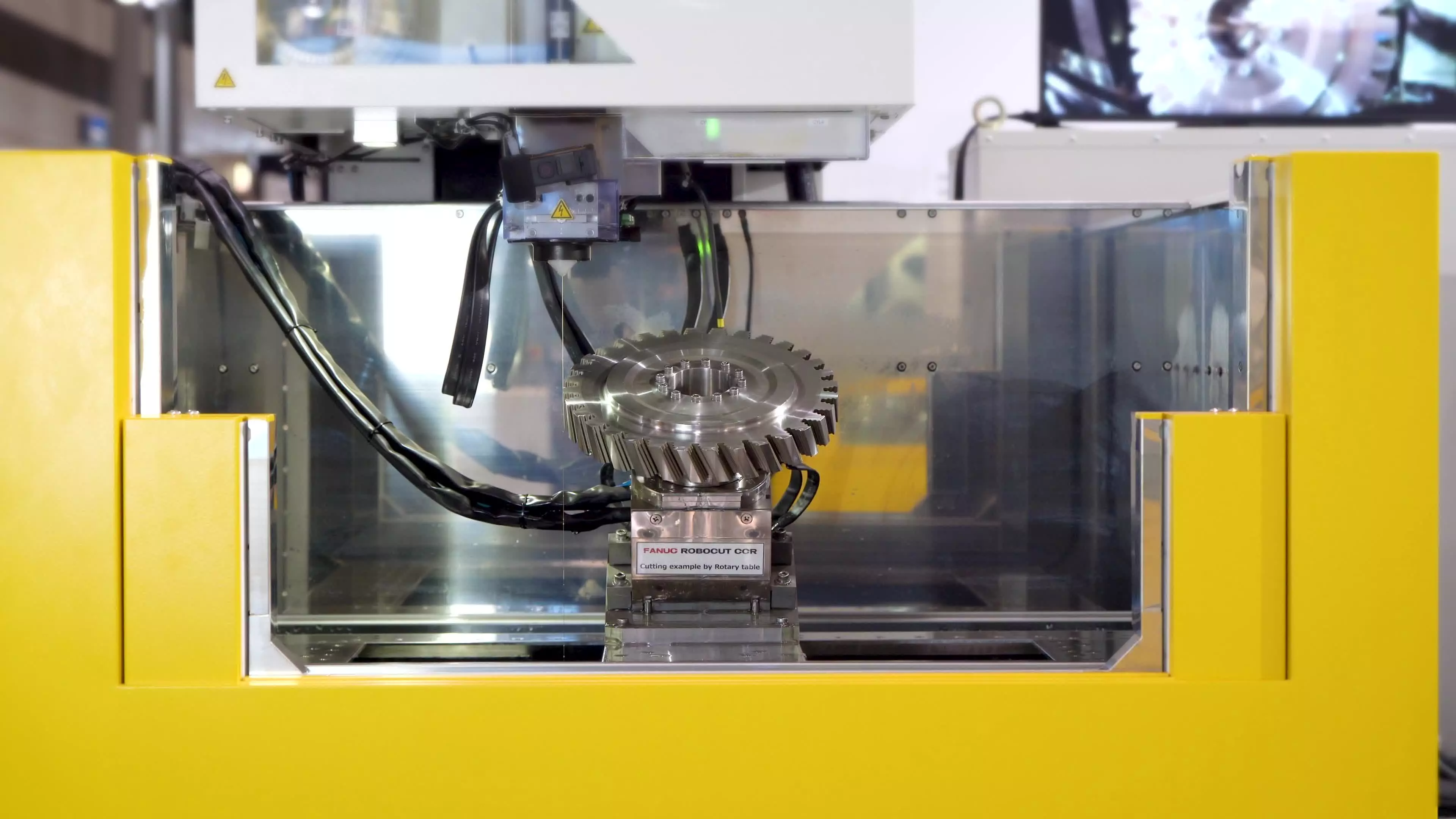

ROBOCUT 𝛼-C800𝑖C

Share

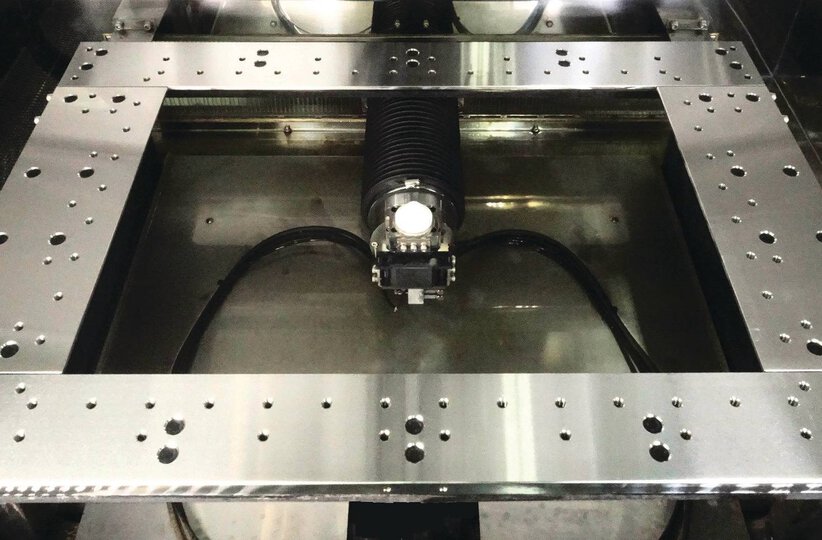

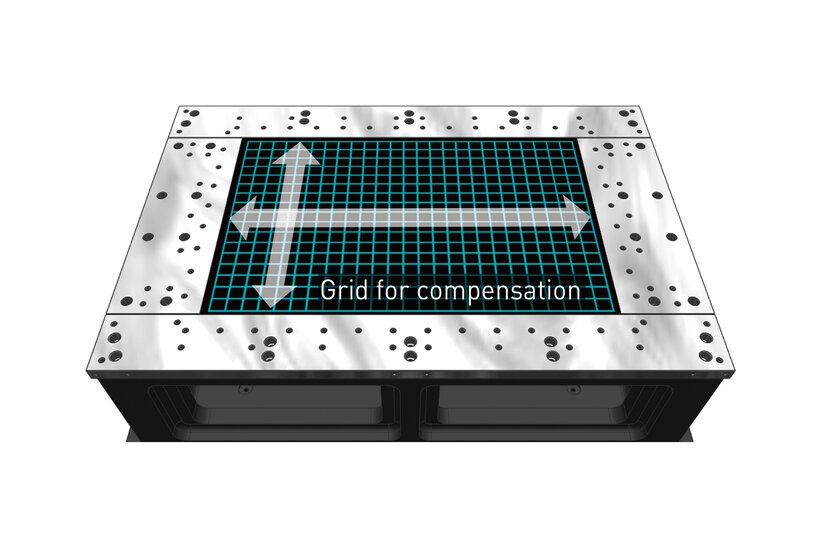

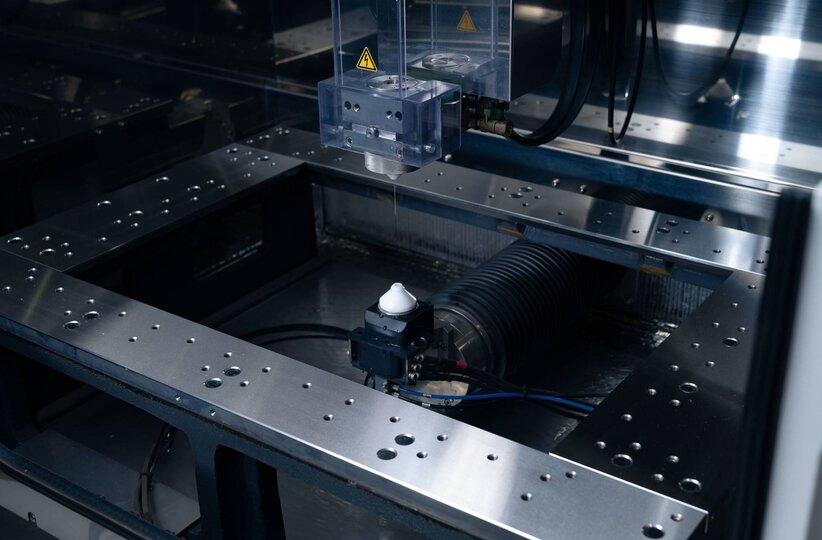

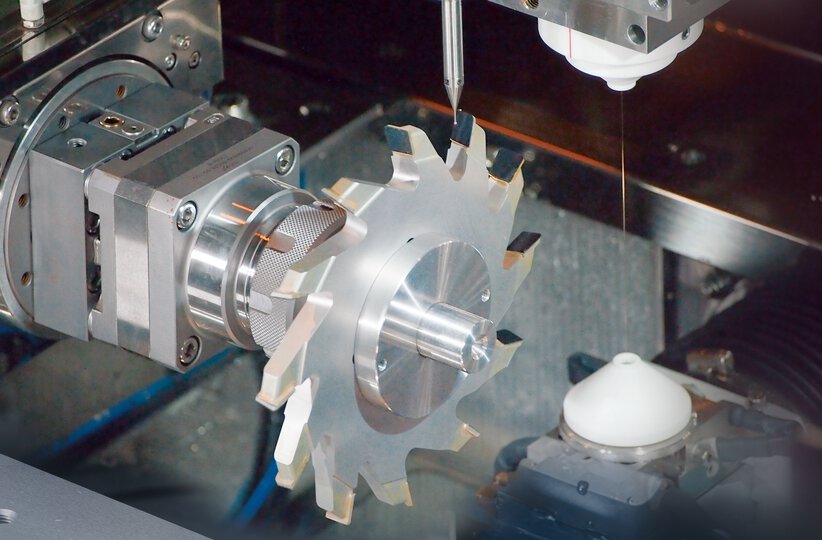

Big-bed versatility at its finest. This powerhouse of a machine redefines what's possible in precision machining with its expansive work surface. Whether you're handling large components, intricate details, or anything in between, the 𝛼-C800𝑖C delivers unrivaled performance. Experience the freedom to tackle diverse projects with ease, making it an ideal choice for industries requiring big-bed capabilities. Explore limitless possibilities with the ROBOCUT 𝛼-C800𝑖C.

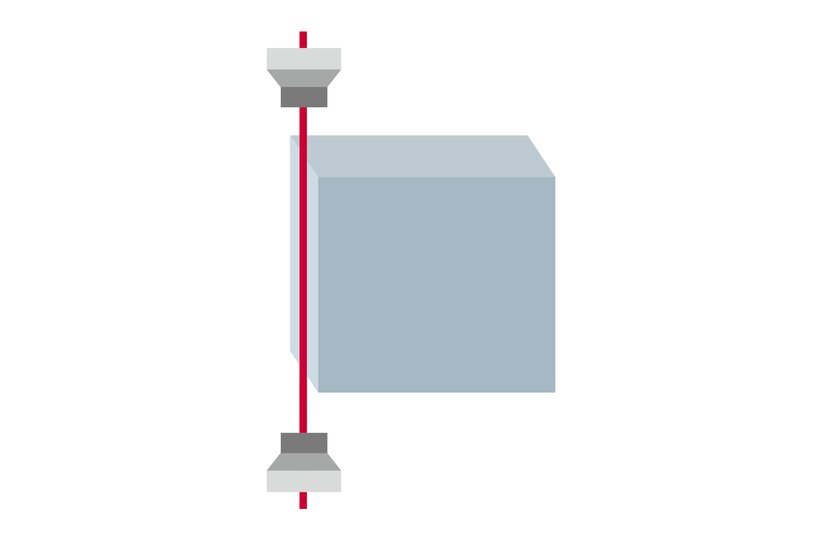

Maximum workpiece dimensions

1250x975x300 mm

Maximum workpiece weight

3000 kg

XY axis table travel

800x600 mm

Get Inspired

Get Inspiration from Other's Success

Haidlmair

FANUC ROBOCUT Machines Underpin Success at Leading Injection Mould Manufacturer

Haidlmair, a top injection mould specialist, invested in two more FANUC ROBOCUT wire EDM machines, continuing a decades-long partnership and legacy of precision.

Perfect Fit for Your Application

Wire Cutting EDM

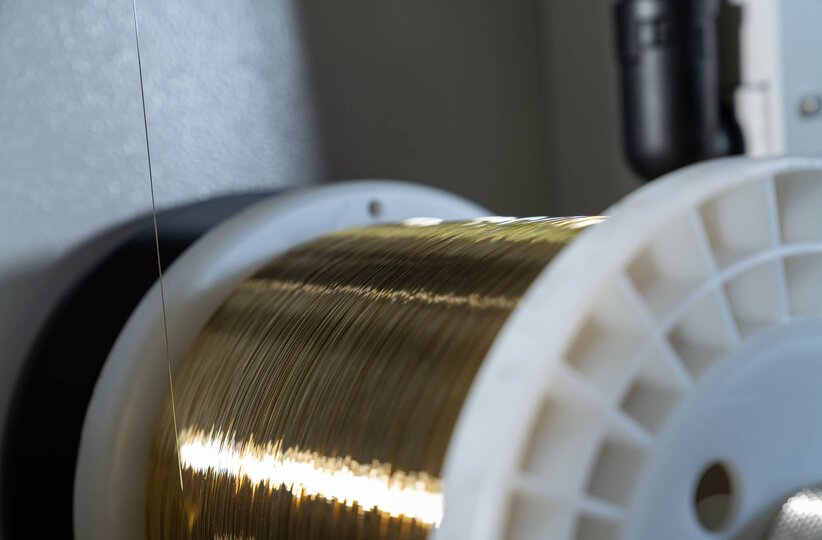

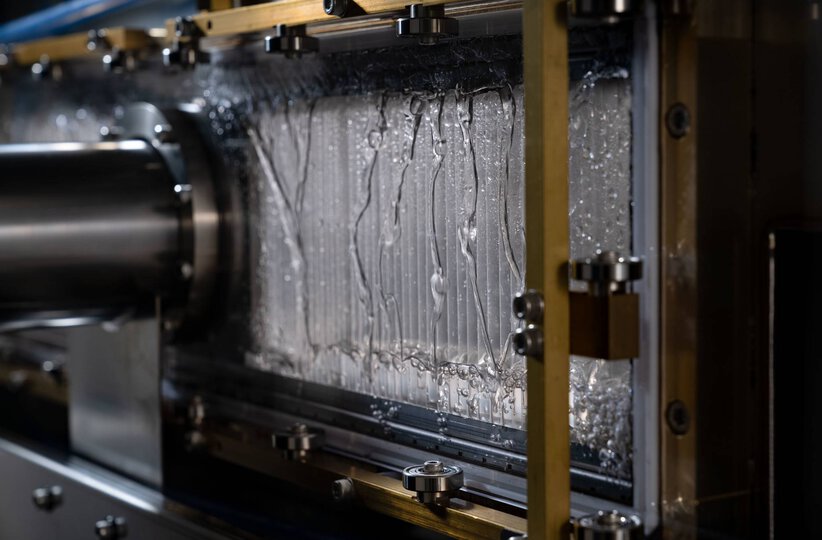

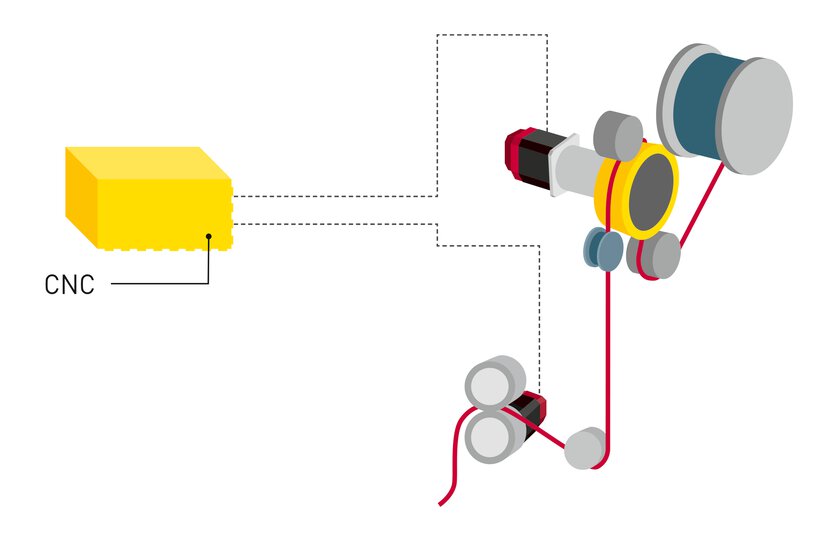

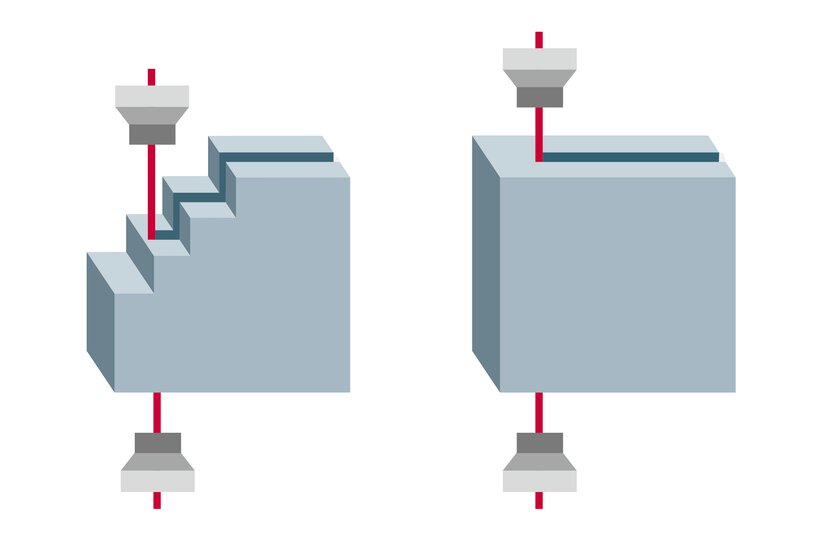

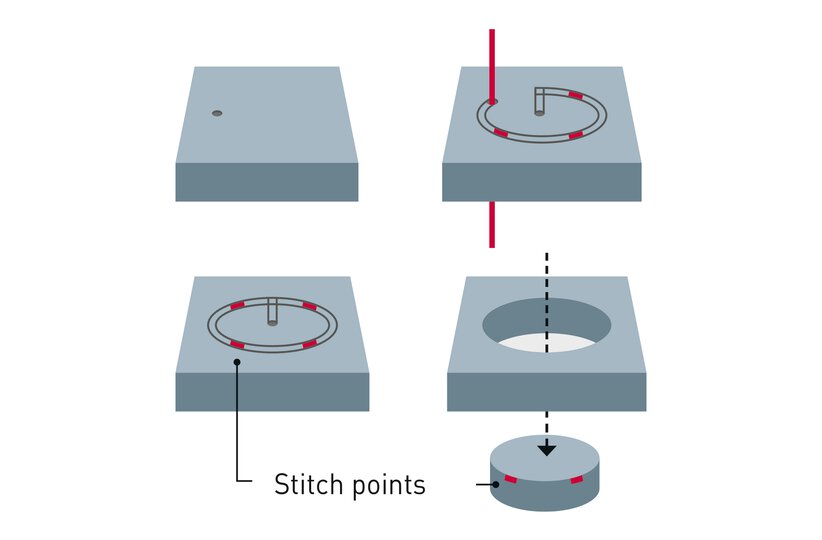

Wire EDM (Electrical Discharge Machining) is a precision manufacturing process that uses a thin, electrically charged wire to cut intricate shapes and contours in hard metals and conductive materials. The wire generates a series of rapid electrical discharges, which erode the material with extreme accuracy without applying mechanical force. This non-contact method allows for the production of highly detailed, complex parts with excellent surface finishes, making it essential for industries that require precise machining, such as aerospace, medical, and mould-making.

Tailored Solutions for Your Industry

Electronics

We provide automated solutions for electronics manufacturing and clean room settings.

Complex Machining for the Aerospace Industry

Optimise Aerospace Manufacturing Processes with FANUC’s State-of-the-Art Complex Machining Solutions!

Complex Machining for the Automotive Industry

Precision and Efficiency in Automotive Manufacturing!

Complex Machining for the Medical industry

Medical Manufacturing Excellence with FANUC's Technology!