ROBOCUT-LINK𝑖

Share

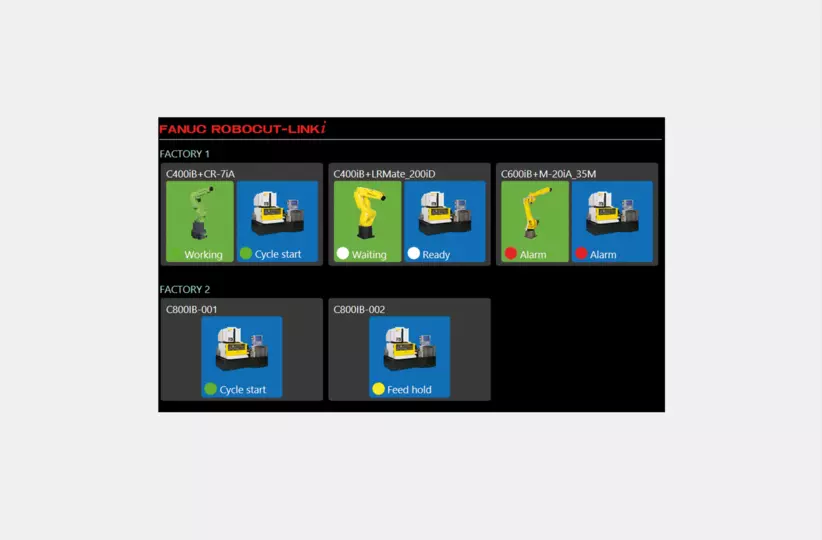

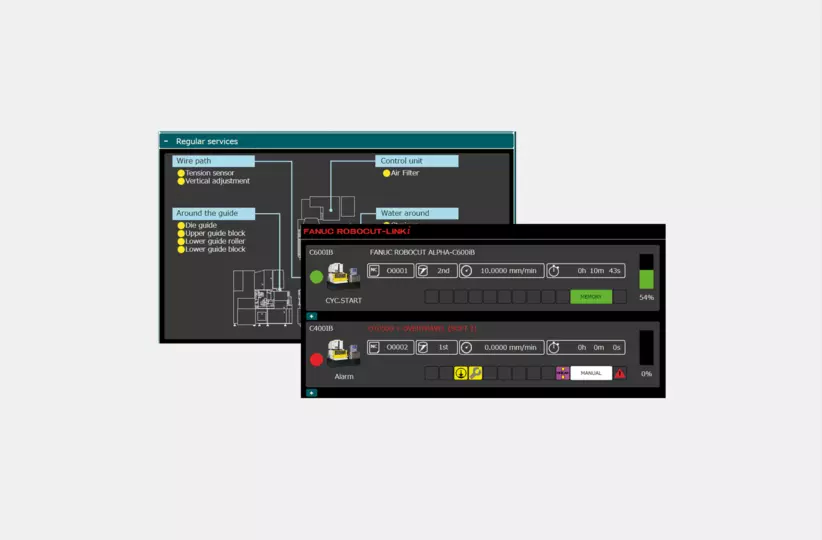

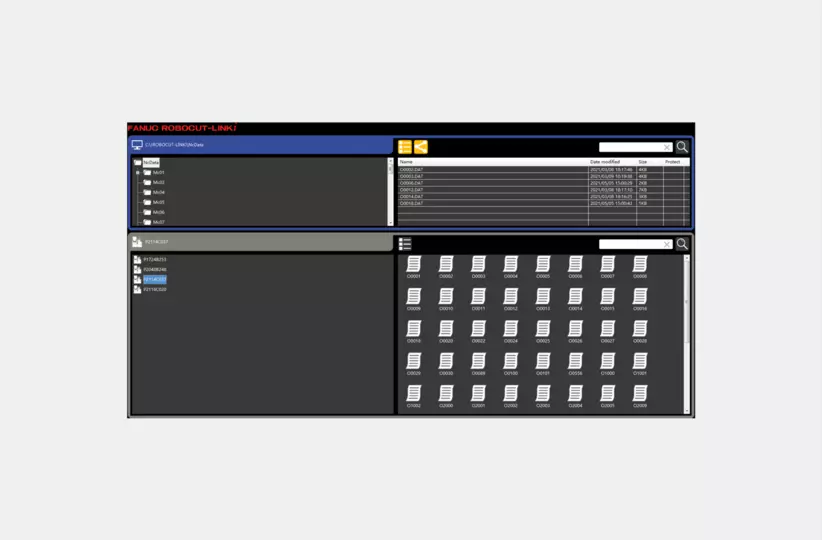

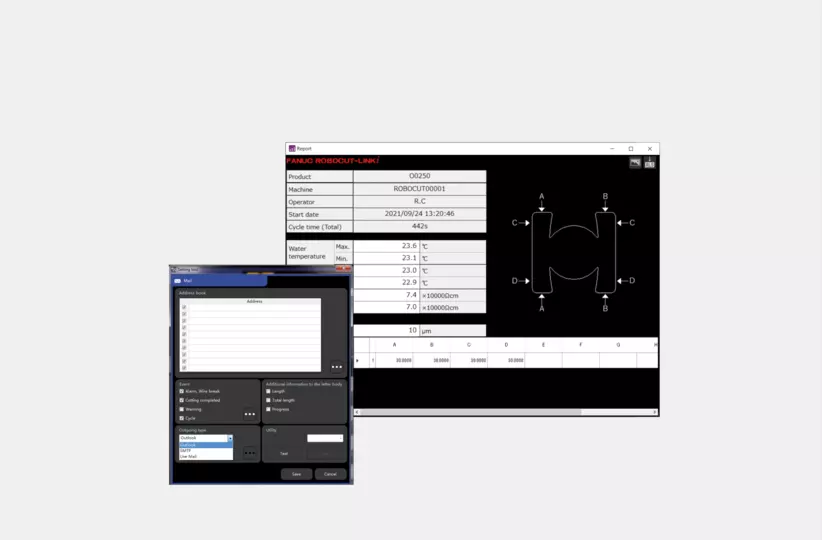

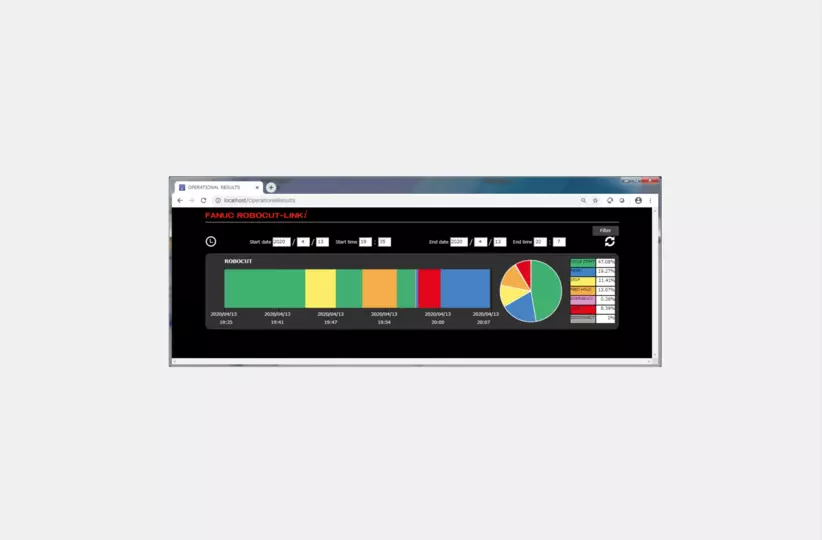

Equipped with a new graphic interface, ROBOCUT-LINK𝑖 is a production and quality information management tool that allows you to monitor the status of up to 32 ROBOCUT machines in real time from remote PCs or smart devices. Specific information is available for each cutting job and event driven push notifications can be sent to different devices. The intuitive user interface gives you access to preventive maintenance functions, estimated consumables levels and recently occurred alarms list. It also allows you to transfer NC programs and run quality checks by comparing baseline data to current cutting statuses.