31𝑖-B5 Plus

Share

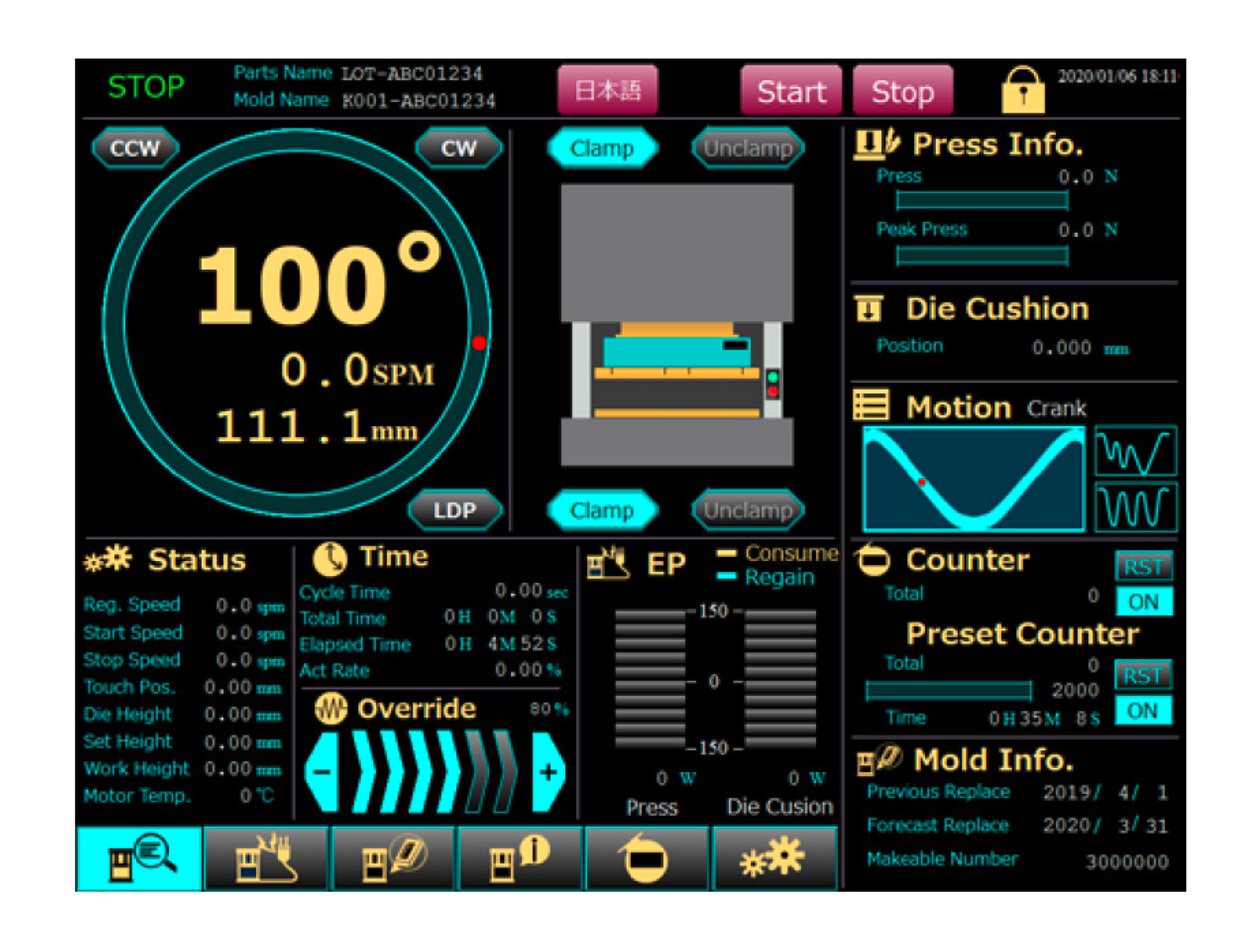

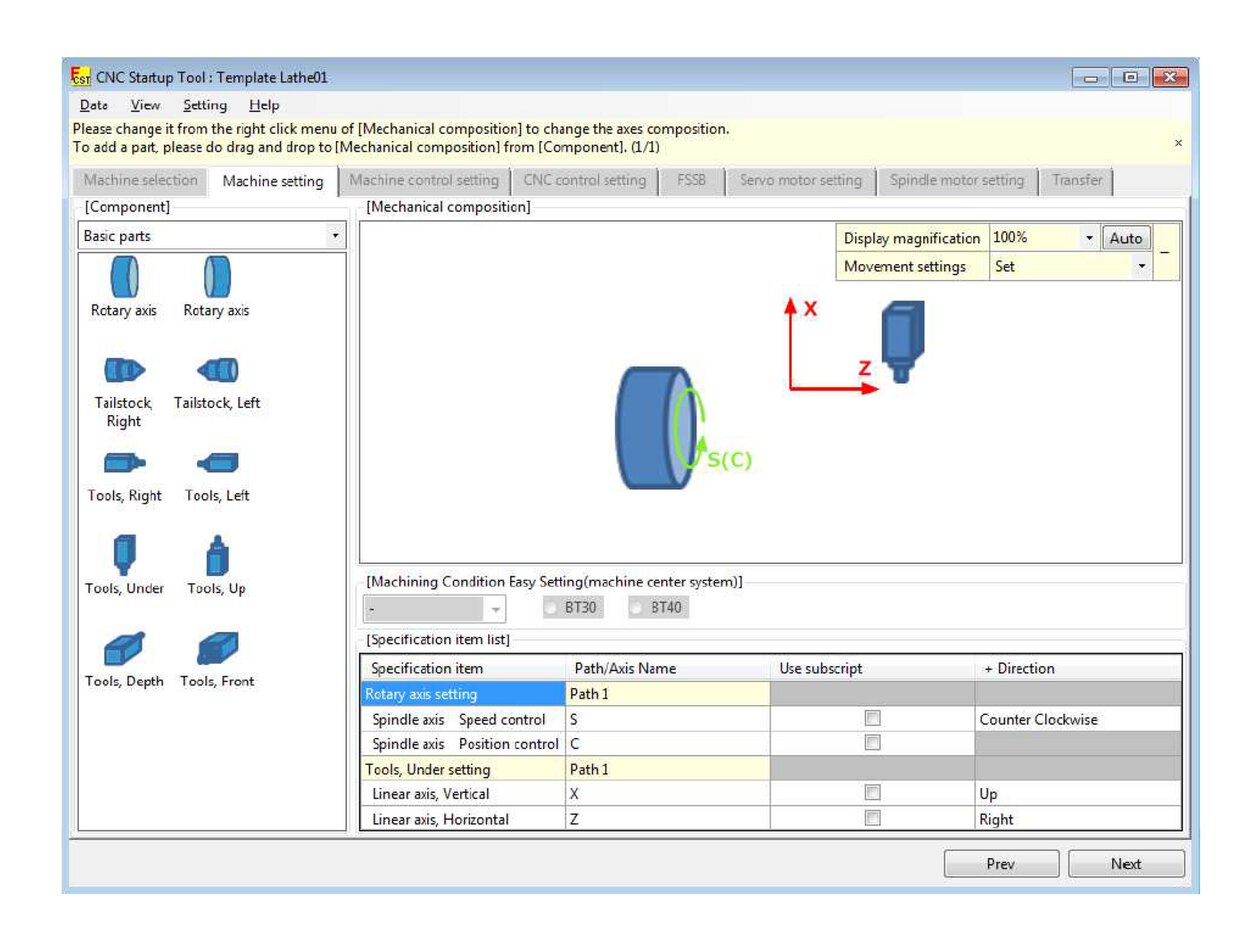

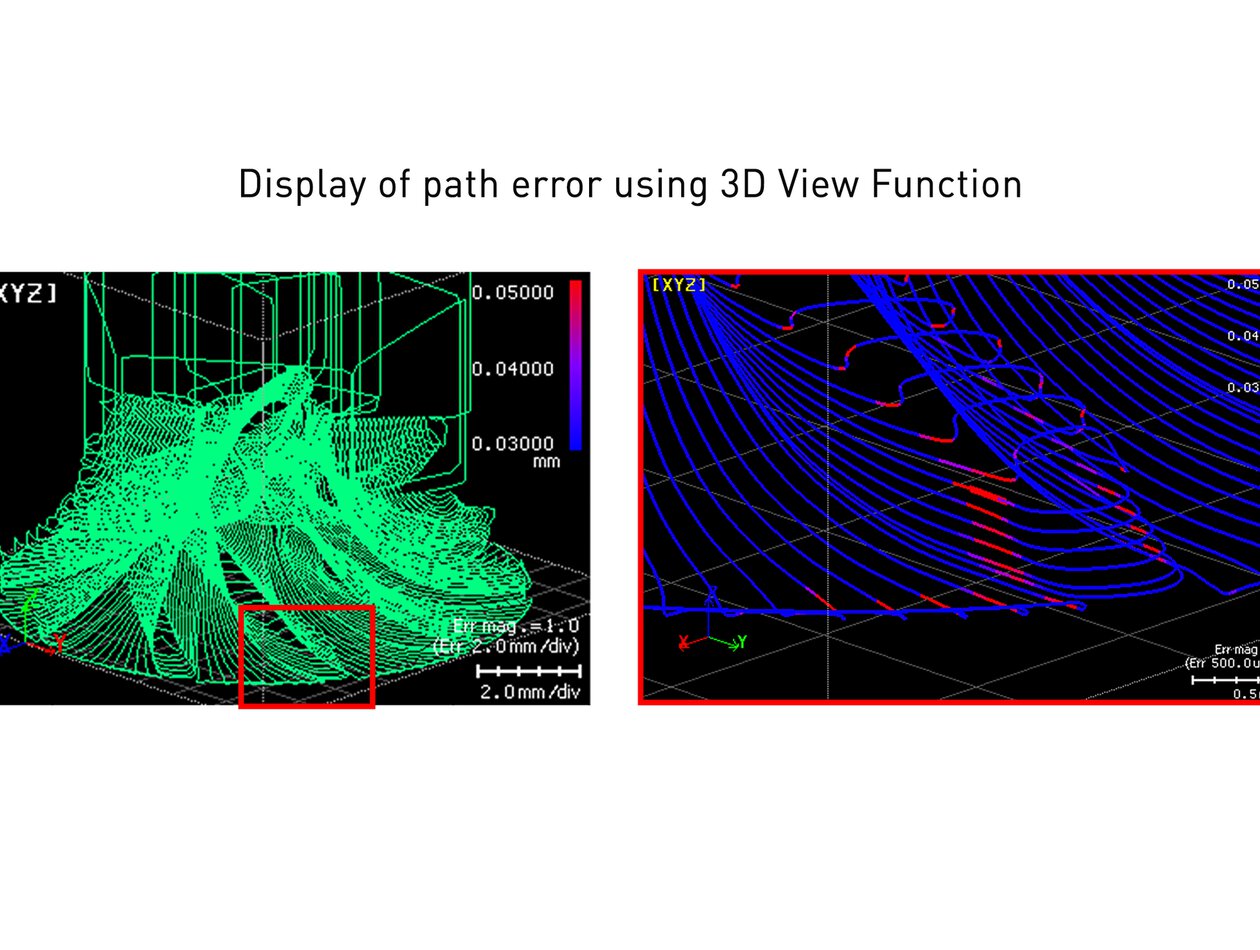

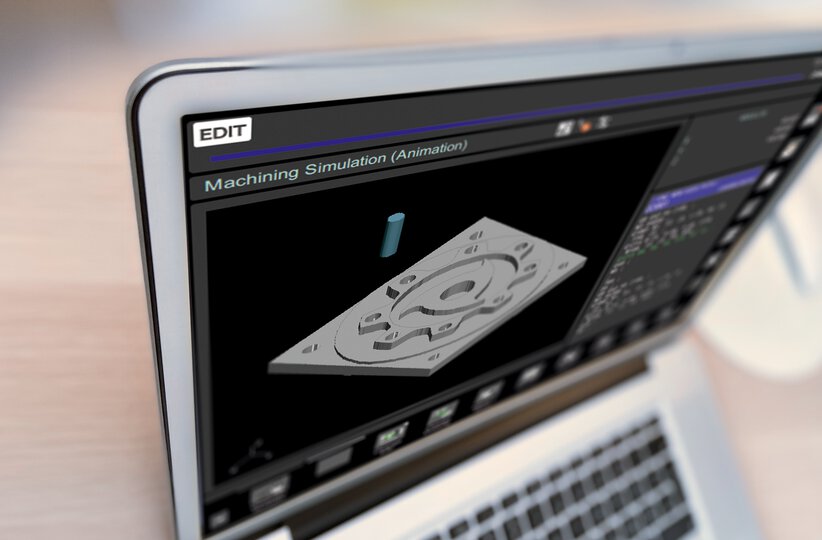

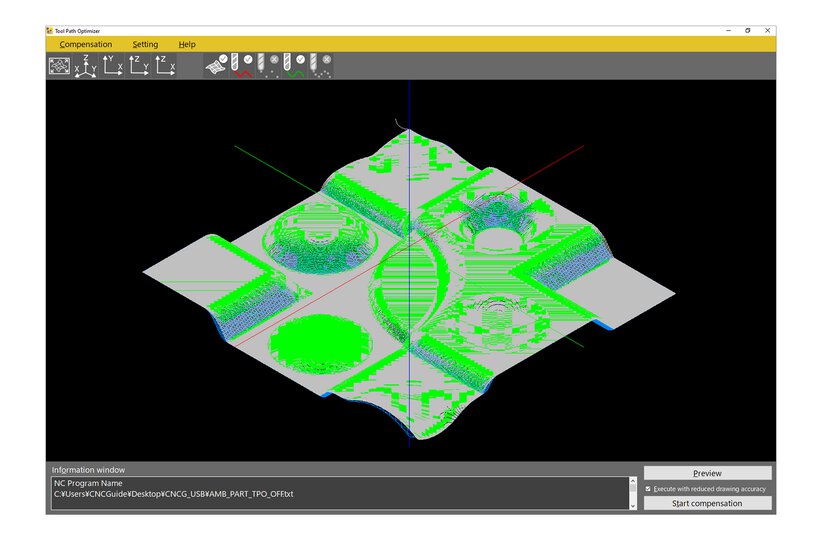

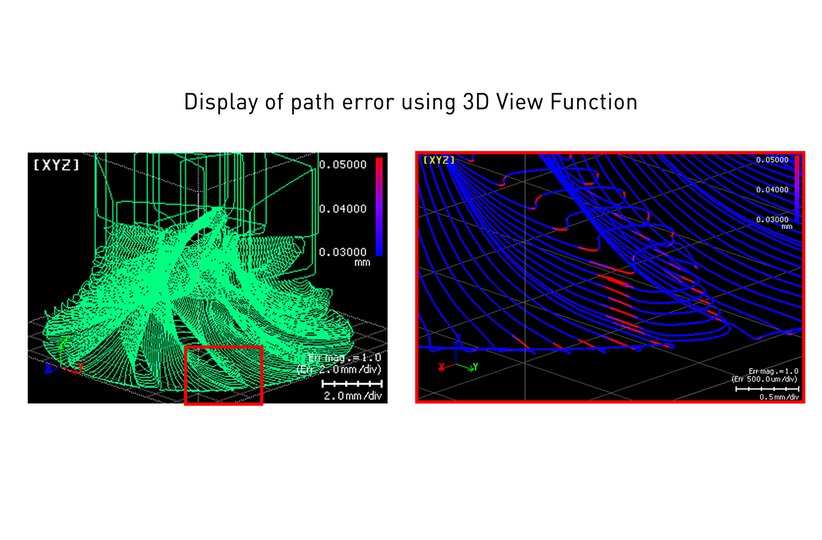

Our CNC 31𝑖-B5 Plus is specifically engineered for enhanced 5-axis operations, delivering superior precision and complex machining capabilities. This advanced control system significantly reduces cycle times, boosting productivity and efficiency in demanding applications. Its robust design and powerful features ensure optimal performance for high-speed, multi-axis machining tasks.

Max. controlled axes total / per path

34/16

Max. spindle axes total / per path

8/4

Max. controlled paths

6

Get Inspired

Get Inspiration from Other's Success

INHOM-98 Ltd.

INHOM-98 Relies on High Quality of FANUC Equipment and Service

When it comes to automating a factory, the reliability of the systems is just as important as their efficiency. An excellent maintenance and repair service can make all the difference.

Perfect Fit for Your Application

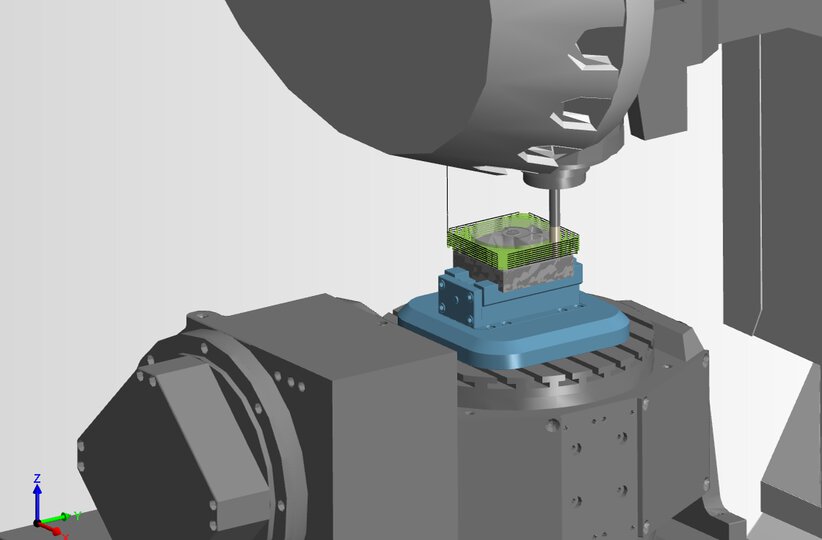

5 Axis Machining

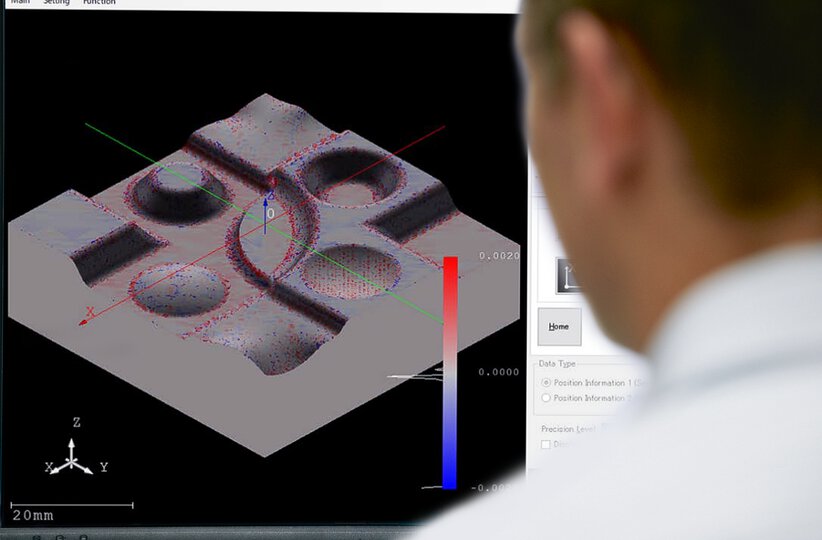

5-axis CNC machining involves simultaneous movement along five axes—three linear (X, Y, Z) and two rotational. This capability allows for the creation of complex parts in a single setup, significantly enhancing precision and efficiency. By moving the cutting tool and workpiece along these five different axes, the 5-axis CNC can produce highly intricate shapes and detailed features.

Tailored Solutions for Your Industry

Complex Machining for the Aerospace Industry

Optimise Aerospace Manufacturing Processes with FANUC’s State-of-the-Art Complex Machining Solutions!

Complex Machining for the Automotive Industry

Precision and Efficiency in Automotive Manufacturing!

Electric Vehicles

No one has more experience automating electric vehicle production than FANUC. Trust us to help automate all of your EV manufacturing processes.

Electronics

We provide automated solutions for electronics manufacturing and clean room settings.

Complex Machining for the Medical industry

Medical Manufacturing Excellence with FANUC's Technology!