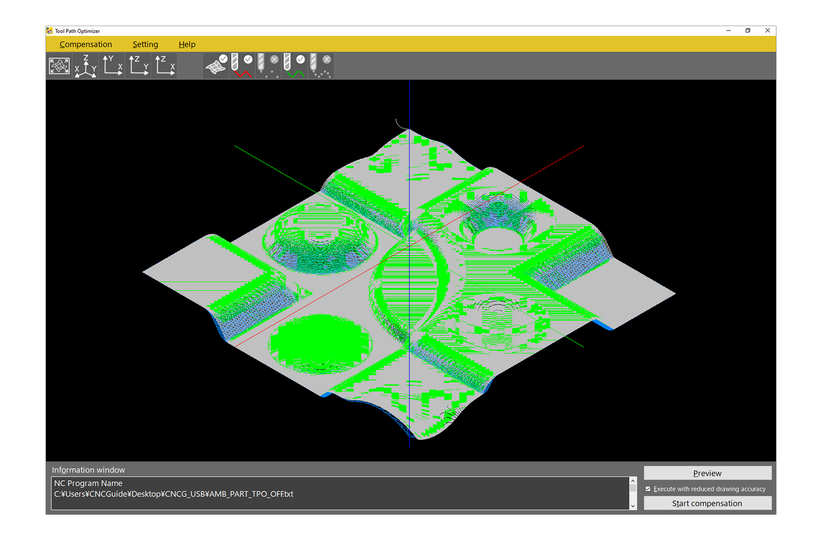

Tool Path Optimizer

Share

Unleash the efficiency of your CNC machines. The challenge: Traditionally generated toolpaths can lead to inefficiencies such as excessive travel time, uneven tool wear and poor surface finish. These issues result in wasted time, increased costs and potential rework. The solution: Our state-of-the-art Toolpath Optimizer analyses your toolpaths and applies advanced algorithms to optimise them. This feature enhances part surface quality and improves machining performance. It prevents scratches and steps on the part surface.