Placing Plastic Injection-Moulding into Packing Trays

Get Inspired

Les robots dans la production laitière

Les tâches de palettisation exigeantes sont un jeu d'enfant pour les robots. Pour les applications complexes, un développement et une conception bien pensés garantissent l'efficacité de la production et la compétitivité.

Un fabricant de cosmétiques voit la beauté de l'automatisation de FANUC

Erkul Cosmetics en Turquie bénéficie d'une myriade d'avantages en termes de qualité et d'efficacité fournis par divers produits d'automatisation FANUC haute performance. Cette entreprise de cosmétiques à croissance rapide cherche à établir une référence pour la fabrication dans son secteur, soutenue par les gains de compétitivité que les solutions FANUC fournissent.

Le robot FANUC s'attaque à l'agriculture

Le levage de charges lourdes et les efforts physiques ne sont plus qu'un lointain souvenir chez Green Services. Le système de palettisation automatisé équipé d'un robot FANUC assure aujourd'hui un fonctionnement sûr et productif.

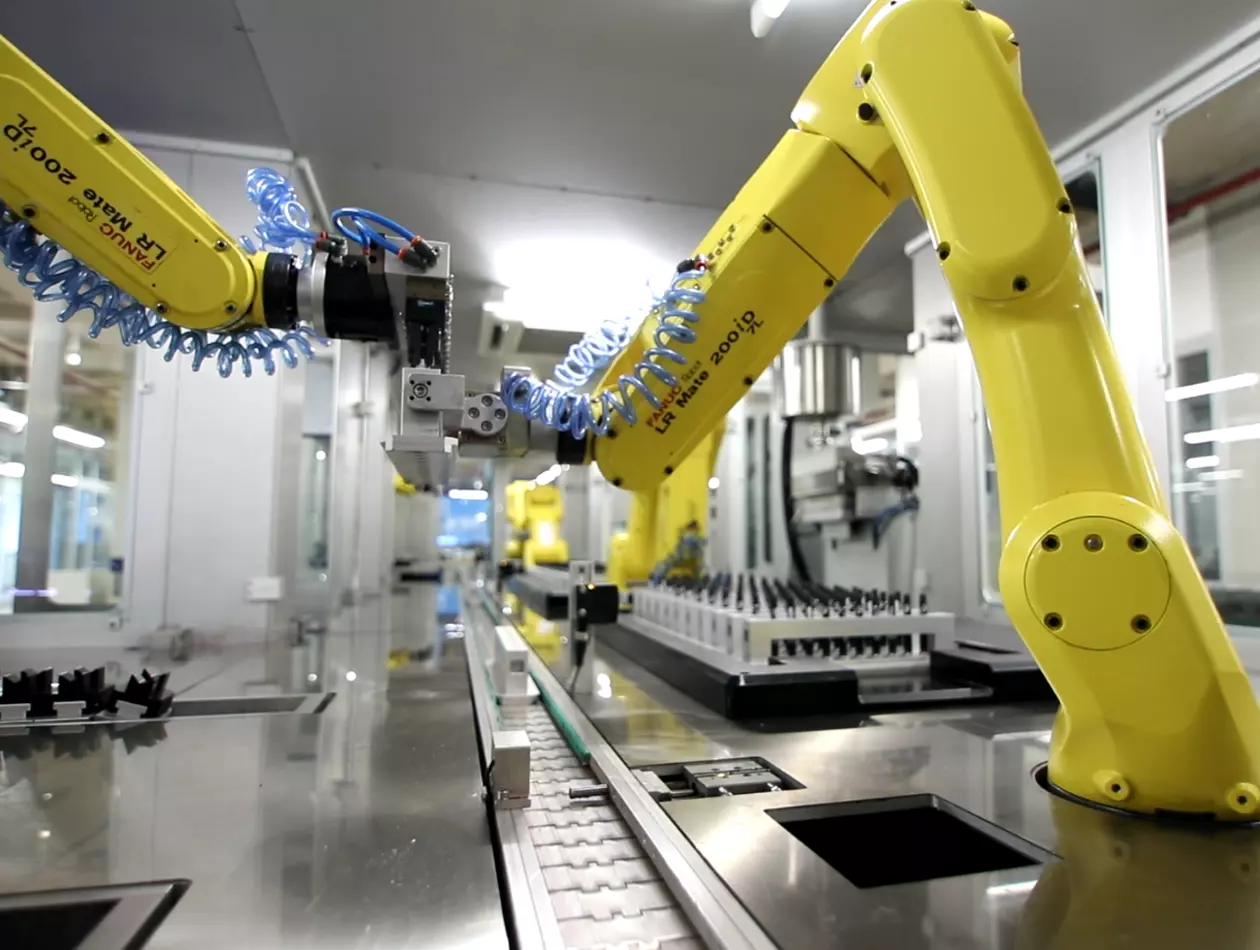

Assemblage entièrement automatisé de moulins à café

Dans la fabrication d'appareils ménagers courants tels que les moulins à café, un certain nombre de conditions préalables déterminent le succès de la production. Par exemple, seuls des processus clairement structurés, efficaces et orientés vers des objectifs précis permettront d'atteindre les niveaux requis de fiabilité de la production. La réalisation de cette ambition devient nettement plus réaliste grâce à l'automatisation, comme le leader du marché Eugster/Frismag AG peut en témoigner après avoir adopté 14 robots industriels FANUC LR Mate et FANUC ZDT (Zero Down Time), qui permettent désormais l'assemblage automatisé en continu d'un moulin à café toutes les 7 secondes.

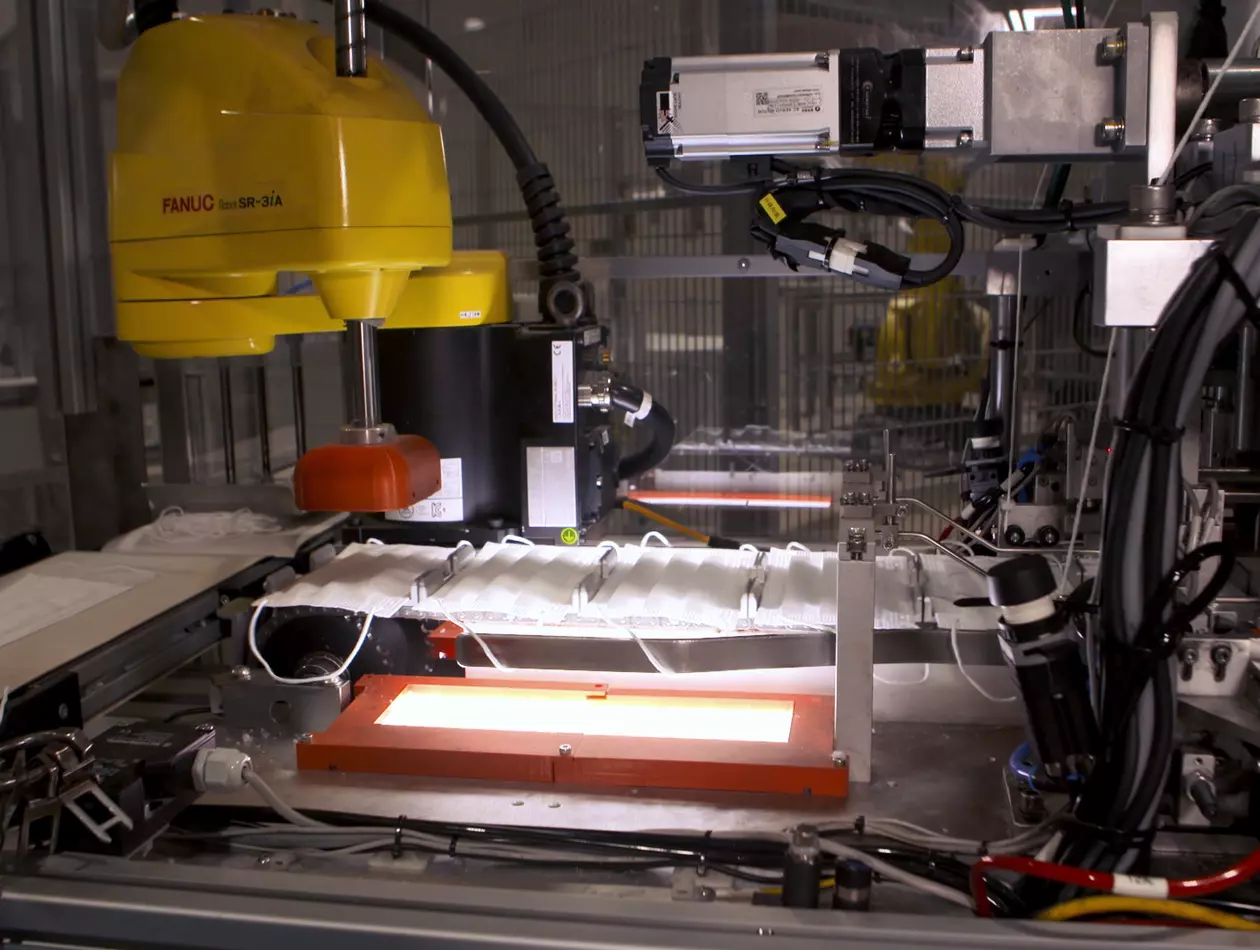

Les robots FANUC aident le producteur de masques à relever le défi

Lorsque la demande de production s'accélère considérablement dans un court laps de temps, les robots et l'automatisation peuvent aider à répondre aux exigences beaucoup plus rapidement que beaucoup ne le pensent. Toutefois, ce résultat dépend fortement de la sélection de robots faciles à installer, à programmer et à mettre en service.

FANUC Case Studies

Explore our comprehensive range of factory automation solutions, showcased in detailed case studies, and designed to optimise and streamline any manufacturing process.

Entretien des machines

Manutention