Палетизиране

Оптимизирайте процеса на опаковане с роботите за палетизиране на FANUC

Роботите палетизатори автоматизират подреждането и организирането на продукти върху палети, като значително подобряват ефективността и намаляват ръчния труд. Използвайки усъвършенствани сензори и програмиране, те прецизно и надеждно обработват различни артикули. Тези роботи рационализират процесите на опаковане, като осигуряват последователно и точно подреждане и повишават цялостната производителност.

Вдъхновете се

Вдъхновявайте се от успехите на другите

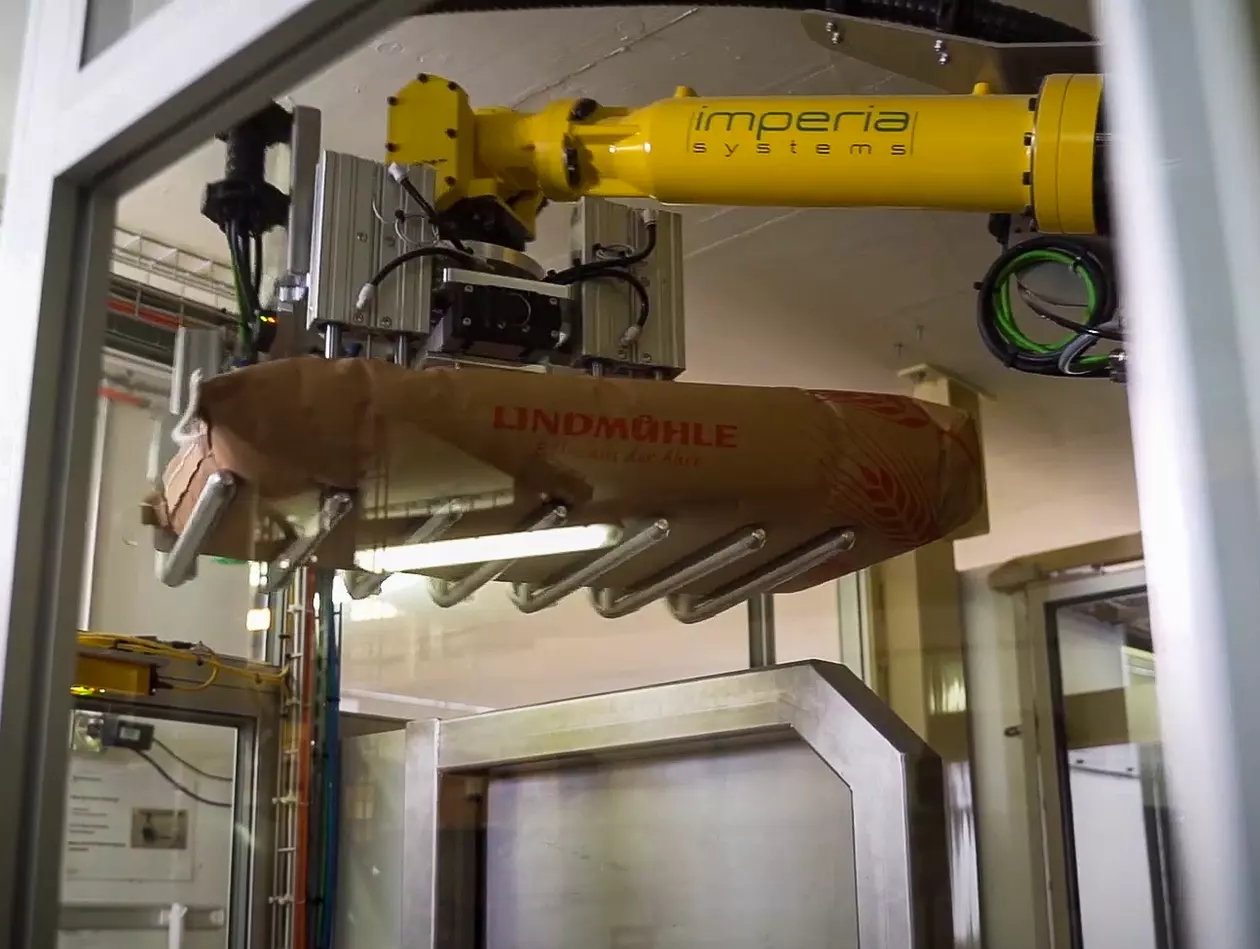

FANUC Robot Raises Palletising Capacity at Flour Plant

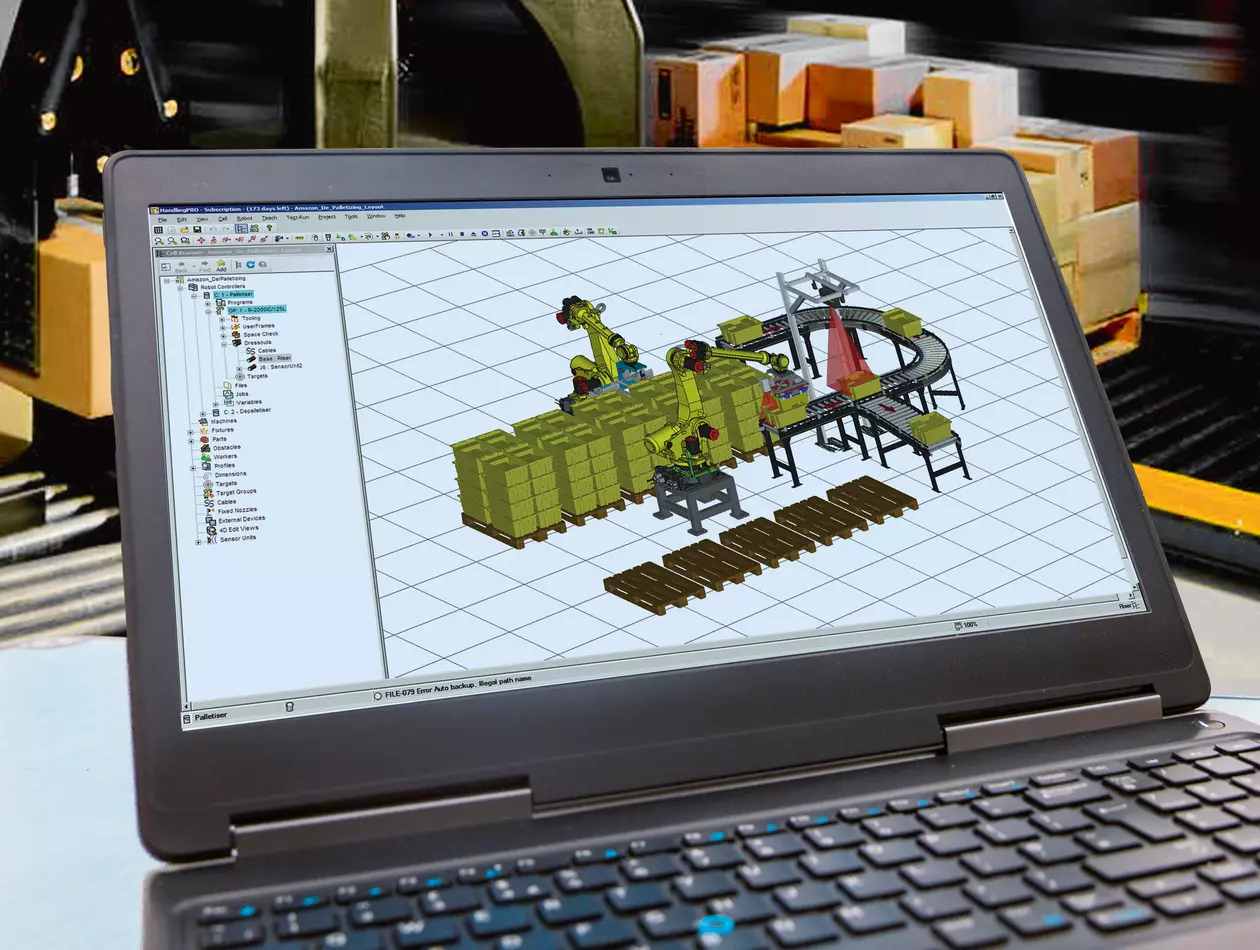

Taking the strain in heavy lifting operations is a classic application for industrial robots. However, implementing robots in lifting tasks not only provides physical relief to workers, it also has the potential to boost throughput, even where space is limited. Flour manufacturer Lindmühle is a case in point, where FANUC simulation software highlighted the optimal robot for the available working envelope.

FANUC Robots Automate Coin Production at Swissmint

Automating the full minting process from individual coins to finished palletised boxes is no mean feat. However, that was the task facing Swissmint, the Federal Mint of Switzerland. To make this complex concept a reality, Swissmint deploys high-performance FANUC robots in tasks that include pick and place, assembly of boxes and palletisation.

Trio of FANUC Robots Boost Packing Efficiency at Inoverde

In a fast-moving fresh-food distribution plant, efficiency through automated packing operations is paramount to keep pace with demand. As a by-product of this approach, robot adopters also gain from less physical strain for employees, gentler handling of delicate produce like fruit and vegetables, and more a uniform and repeatable process. Among the latest factories to benefit from all this added value is the Bätterkinden, Switzerland facility of major food distributor Inoverde, where carrot filling, packing and palletising operations are benefiting from the introduction of three FANUC industrial robots.

FANUC Robot Ends Packaging Bottleneck at Food Factory

When implementing improvements to a bottleneck process the common outcome is the emergence of a new bottleneck elsewhere in the factory. Whereas in years gone by this situation would necessitate the recruitment of more labour, automation has today become industry’s go-to solution for bottlenecks. Just ask Brunos, a leading producer of salad dressings, which knows all about the benefits that a robot can bring.

Преобразувайте индустрията си с роботите за палетизиране на FANUC

Автомобилна индустрия

Aerospace

Храни и напитки

Складиране

Медицински

Електрически превозни средства

Всички отрасли

Научете повече за нашите безкрайни възможности

Нашите решения за други приложения

Повишаване на ефективността, прецизността и производителността с решенията на FANUC за различни приложения

Ние предлагаме решения за подобряване на производствените процеси - от високопрецизни роботи до интелигентна автоматизация.