M-410/800F-32C

Share

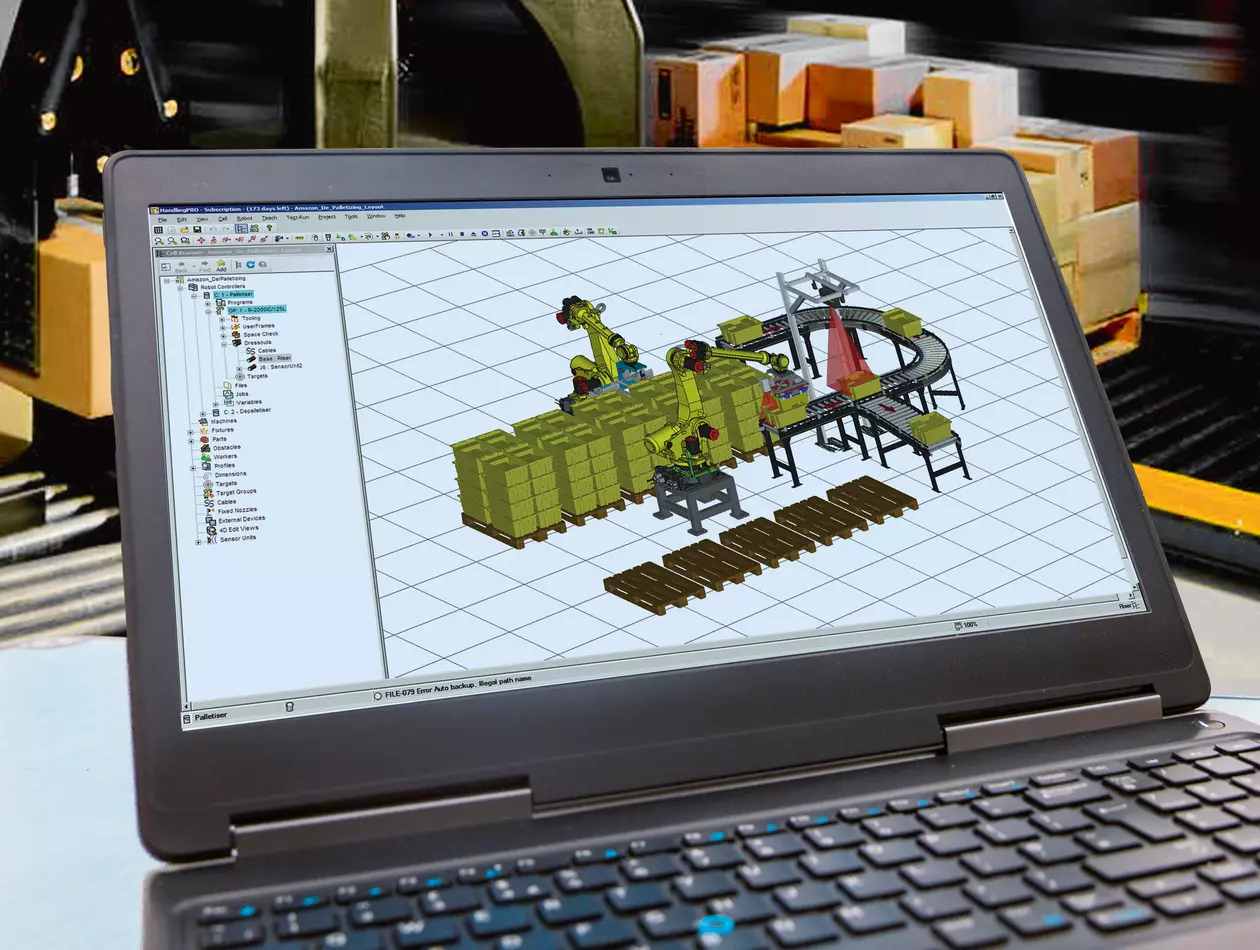

The M-410/800F-32C is a high-performance palletising robot built for demanding industrial tasks. With a payload capacity of up to 800 kg, it effortlessly handles heavy and bulky items with speed and accuracy. Its hollow wrist design minimises cable interference, reducing wear and maintenance while improving operational reliability. Engineered for maximum throughput, this robot is ideal for palletising and loading/unloading applications where efficiency and uptime are critical. Whether in manufacturing, logistics, or warehousing, the M-410/800F-32C delivers consistent, high-volume performance—making it a smart investment for businesses focused on productivity and long-term operational gains.

Robot Payload

800 kg

Robot Reach

3203 mm

Axes

4

Get Inspired

Perfect Fit for Your Application

Palletising

Automating your palletising process can boost both the safety and efficiency of your operations. With a wide range of options to choose from, you’ll find the perfect fit for various sizes, payloads, cycle times, and precision needs, all while ensuring your products are handled with the utmost care.

Material Handling

Automise material handling with industrial robots to unlock numerous advantages for your business. Significantly enhance efficiency and productivity by reducing the time and effort required for manual handling. Let robots operate continuously without fatigue to ensure consistent performance and minimise errors, leading to higher throughput and faster processing times.

Tailored Solutions for Your Industry

Robotics & Automation for the Aerospace Industry

FANUC’s advanced robotics: optimising aerospace manufacturing processes.

Food & Beverage

Food & beverage is our bread & butter. Contact us today to put our experience in robots in food & beverage industry to work for you.

Robotics & Automation for the Medical Industry

Enhancing medical industry efficiency through robotics and automation!

Warehousing, Logistics, Post & Parcel

FANUC's wide offer of warehouse robots fit the needs of anyone looking to apply automation to their warehouse, distribution center, fulfillment center, and more.