M-3𝑖A/6S

Share

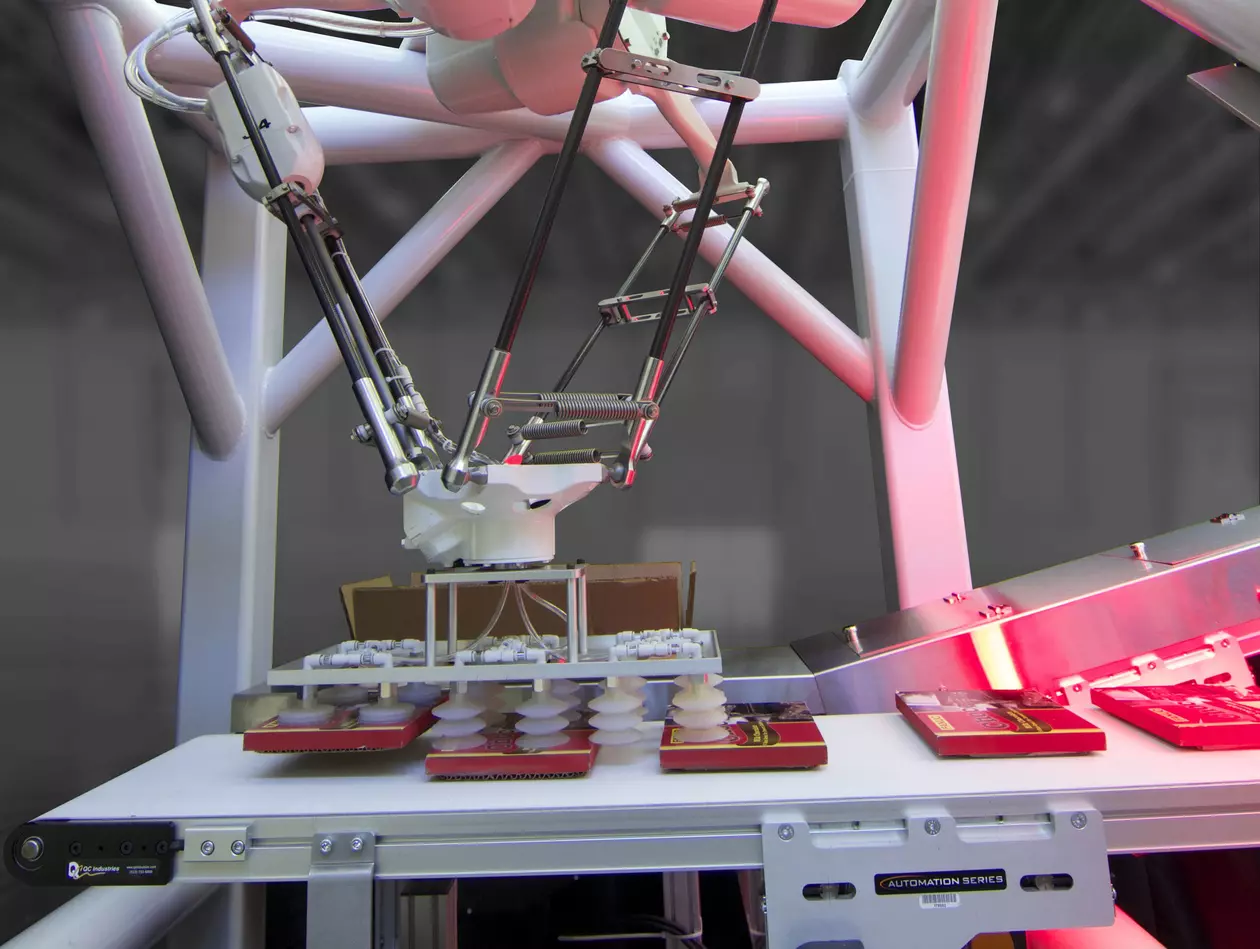

The M-3𝑖A/6S is a Delta robot renowned for its efficiency in high-speed picking operations. Equipped with powerful servomotors, it achieves rapid acceleration and notably short cycle times, ideal for dynamic production environments. This model features four axes and a high-speed single-axis wrist, enhancing its dexterity and precision. Its extended reach is perfectly suited for picking tasks across multiple conveyors, making it an essential component in streamlining your automated processes.

Robot Payload

6 kg

Robot Reach

1350 mm

Axes

4

Get Inspired

Perfect Fit for Your Application

Assembling

Automate assembly processes with robots to achieve significant advantages over manual methods. Ensure unparalleled precision and consistency, reducing errors and guaranteeing high-quality output. Increase production speed by enabling continuous operation without fatigue, which boosts throughput. Elevate efficiency, quality, and safety, making automation a strategic investment for any manufacturing operation.

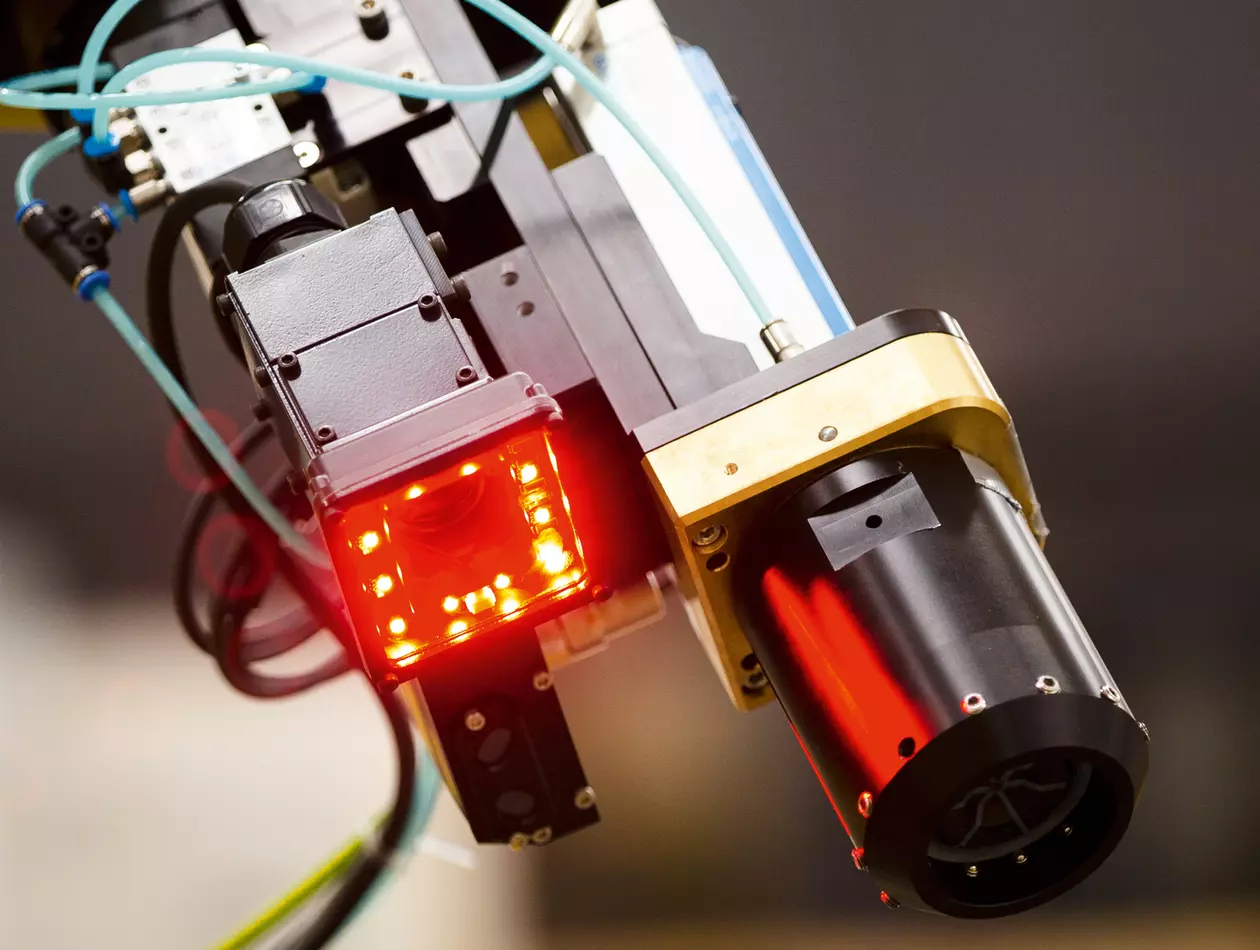

Vision Inspection

Vision inspection technology enhances your manufacturing processes with image-based automated systems that accurately inspect and analyse objects. Advanced vision inspection solutions use cutting-edge cameras, sensors, and software to capture and process images, detect defects, measure dimensions, and ensure your products meet the highest quality standards.

Tailored Solutions for Your Industry

Robotics & Automation for the Automotive Industry

Automotive excellence: FANUC's versatile automation solutions.

Electric Vehicles

No one has more experience automating electric vehicle production than FANUC. Trust us to help automate all of your EV manufacturing processes.

Electronics

We provide automated solutions for electronics manufacturing and clean room settings.

Food & Beverage

Food & beverage is our bread & butter. Contact us today to put our experience in robots in food & beverage industry to work for you.

Robotics & Automation for the Medical Industry

Enhancing medical industry efficiency through robotics and automation!

Warehousing, Logistics, Post & Parcel

FANUC's wide offer of warehouse robots fit the needs of anyone looking to apply automation to their warehouse, distribution center, fulfillment center, and more.