M-10𝑖D/10L

Share

The M-10𝑖D/10L has an extended reach and fast precision. This long arm model excels at handling tasks with unparalleled speed and accuracy. Its slim design and small footprint make it perfect for compact workspaces. Designed for tight installations, this versatile robot has exceptional horizontal stroke capacity, allowing it to handle larger parts up to 10 kg. Its versatility is further enhanced by its ability to be mounted upside down or at an angle, providing flexibility for different applications. Ideal for high throughput robotic palletising where reliability and speed are paramount.

Robot Payload

10 kg

Robot Reach

1636 mm

Axes

6

Get Inspired

Get Inspiration from Other's Success

Kunstoff-Packungen AG

Placing Plastic Injection-Moulding into Packing Trays

Because manufacturers everywhere face shortages of skilled labor, and as a company dedicated to excellence, Kunstoff-Packungen continuously seeks ways to improve its level of automation.

Perfect Fit for Your Application

Machine Tending

Automate machine tending with robots to significantly enhance your production by providing superior accuracy and continuous operation, unlike manual tending. Increase efficiency, achieve consistent output, and reduce labour costs and add substantial value to your entire production process.

Material Handling

Automise material handling with industrial robots to unlock numerous advantages for your business. Significantly enhance efficiency and productivity by reducing the time and effort required for manual handling. Let robots operate continuously without fatigue to ensure consistent performance and minimise errors, leading to higher throughput and faster processing times.

Assembling

Automate assembly processes with robots to achieve significant advantages over manual methods. Ensure unparalleled precision and consistency, reducing errors and guaranteeing high-quality output. Increase production speed by enabling continuous operation without fatigue, which boosts throughput. Elevate efficiency, quality, and safety, making automation a strategic investment for any manufacturing operation.

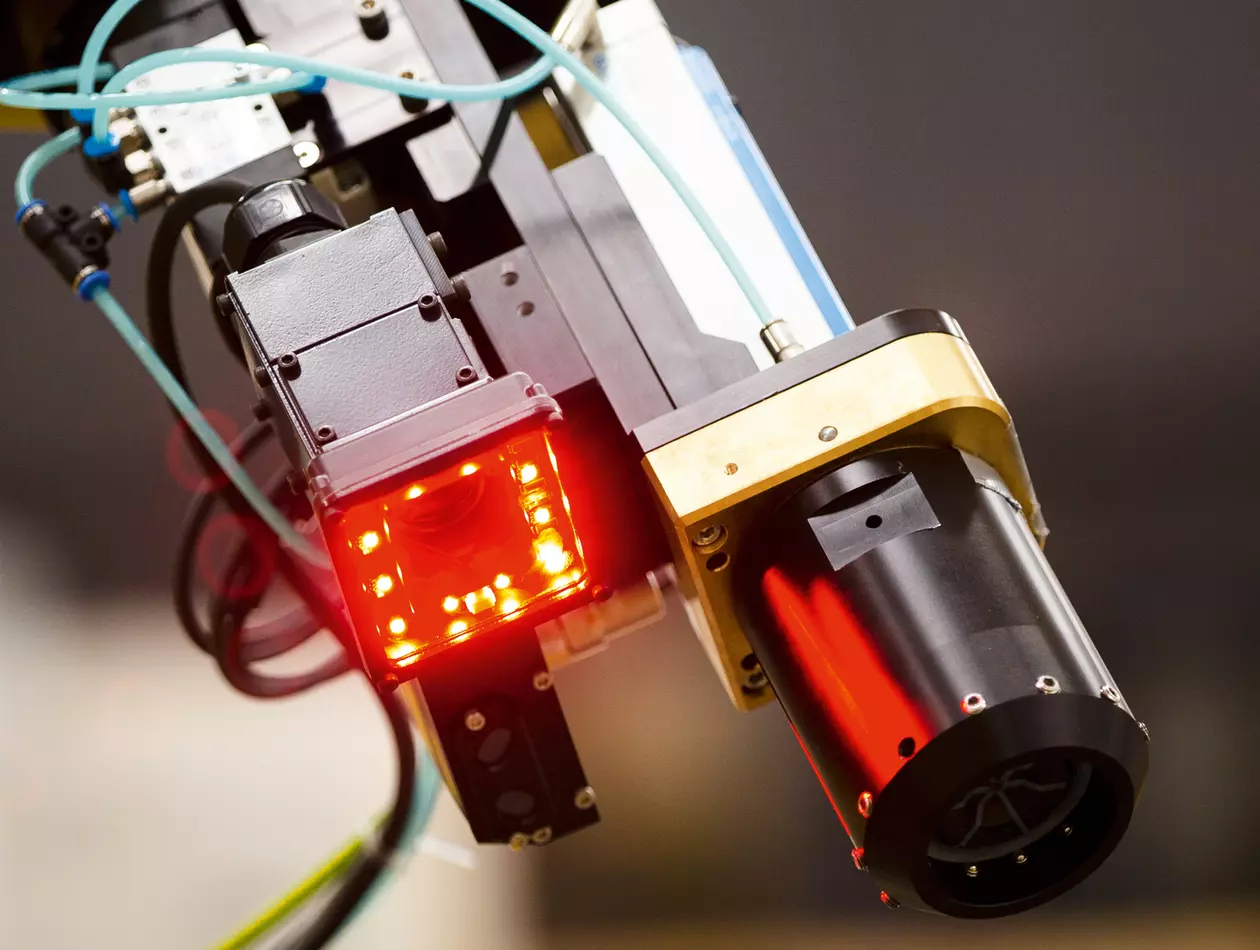

Vision Inspection

Vision inspection technology enhances your manufacturing processes with image-based automated systems that accurately inspect and analyse objects. Advanced vision inspection solutions use cutting-edge cameras, sensors, and software to capture and process images, detect defects, measure dimensions, and ensure your products meet the highest quality standards.

Tailored Solutions for Your Industry

Robotics & Automation for the Aerospace Industry

FANUC’s advanced robotics: optimising aerospace manufacturing processes.

Robotics & Automation for the Automotive Industry

Automotive excellence: FANUC's versatile automation solutions.

Electric Vehicles

No one has more experience automating electric vehicle production than FANUC. Trust us to help automate all of your EV manufacturing processes.

Electronics

We provide automated solutions for electronics manufacturing and clean room settings.

Food & Beverage

Food & beverage is our bread & butter. Contact us today to put our experience in robots in food & beverage industry to work for you.

Robotics & Automation for the Medical Industry

Enhancing medical industry efficiency through robotics and automation!

Warehousing, Logistics, Post & Parcel

FANUC's wide offer of warehouse robots fit the needs of anyone looking to apply automation to their warehouse, distribution center, fulfillment center, and more.