Joseph Martin

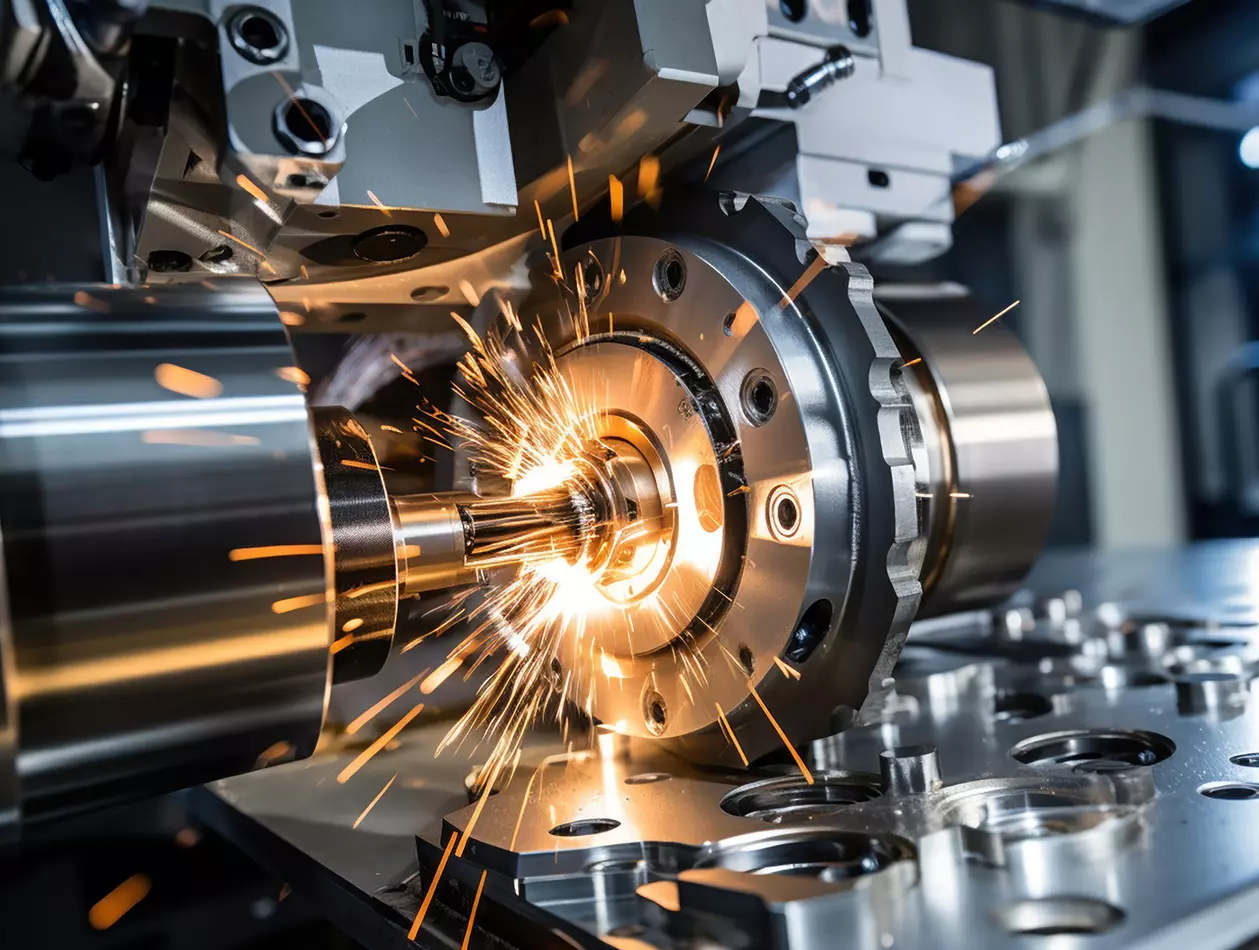

FANUC Solutions Provide Common Thread at Screw-Cutting Specialist

Moving from labour-based to automated production operations can sometimes appear daunting. And yet, with the right technology partner on-board, processes such as automated machining and assembly can come to realisation with relative ease, instantly delivering new levels of productivity and reliability.

Share

FANUC products ensure enhanced productivity, repeatability and cost-efficiency.

FANUC ROBOCUT wire EDM running reliably for more than 30 years.

Extremely low failure rate across the entire suite of FANUC products on site.

Reliable FANUC customer support.

Get Inspired

FANUC Case Studies

Explore our comprehensive range of factory automation solutions, showcased in detailed case studies, and designed to optimise and streamline any manufacturing process.

Wire Cutting EDM

Wire EDM (Electrical Discharge Machining) is a precision manufacturing process that uses a thin, electrically charged wire to cut intricate shapes and contours in hard metals and conductive materials. The wire generates a series of rapid electrical discharges, which erode the material with extreme accuracy without applying mechanical force. This non-contact method allows for the production of highly detailed, complex parts with excellent surface finishes, making it essential for industries that require precise machining, such as aerospace, medical, and mould-making.

CNC Milling

CNC milling is a machining process that uses computer-controlled rotating cutting tools to remove material from a workpiece to create a desired shape. It is widely used for producing precision parts with complex geometries. The process involves securing the workpiece on a movable table and using various tools to cut, drill, and shape the material based on programmed instructions.

CNC Turning

CNC turning is a machining process where a cutting tool removes material from a rotating workpiece to create precise cylindrical shapes. It is ideal for producing parts with complex geometries and tight tolerances. In order to maximise your turning centre or lathe’s output, having a good CNC capable of managing and optimising a whole array of turning processes is essential. In addition to maximising productivity, a good CNC will also provide you with the flexibility to reduce turnaround times on small batches.

Complex Machining for the Automotive Industry

Precision and Efficiency in Automotive Manufacturing!