Simon

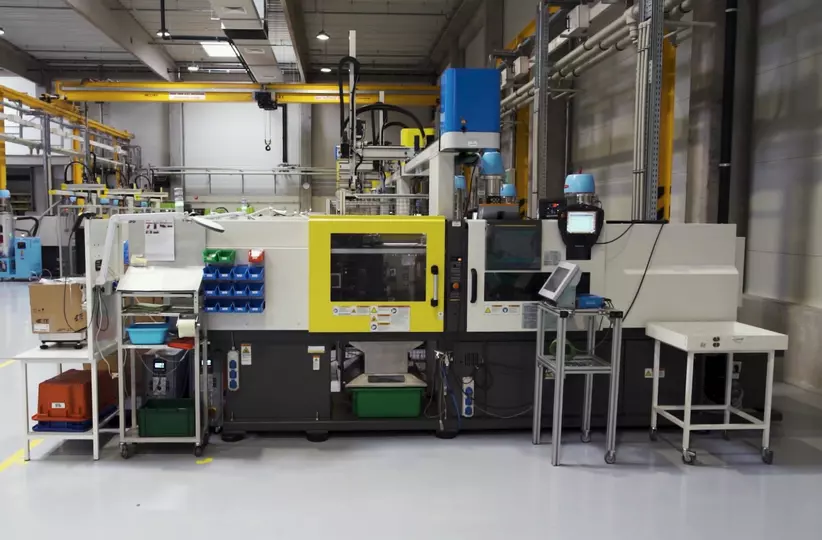

FANUC ROBOSHOT Machines Keep Things Simple for SIMON

High-volume plastics parts; thin walls; zero defects; short automotive lead times; demanding energy efficiency requirements. A growing number of manufacturers are combatting these common challenges by investing in ROBOSHOT high-performance, all-electric injection moulding machines from FANUC. Among their number is SIMON Plastics.

Injection MouldingAdvanced Injection Moulding for the Automotive IndustryAdvanced Injection Moulding for the Medical Industry

Share

Highly responsive FANUC team delivers first ROBOSHOT all-electric injection moulding machine in just two weeks.

SIMON Plastics has 11 ROBOSHOT machines in operation producing high-volume automotive parts.

FANUC ROBOSHOT all-electric injection moulding machines have been selected for their energy efficiency.

FANUC servo-motor technology helps ROBOSHOT machines quickly reach the ideal moulding speed.

Get Inspired

FANUC Case Studies

Explore our comprehensive range of factory automation solutions, showcased in detailed case studies, and designed to optimise and streamline any manufacturing process.

Injection Moulding

Injection moulding is a highly efficient manufacturing process that enables the production of complex, high-quality plastic components with precision and consistency. Utilising advanced automation and robotics, this technology is essential for industries requiring large-scale production, ensuring cost-effective solutions without compromising on the integrity or performance of the final product.

Advanced Injection Moulding for the Automotive Industry

Automotive Injection Moulding Excellence with FANUC’s Technology!

Advanced Injection Moulding for the Medical Industry

Consistency and Reliability in Medical Manufacturing Processes!