/

Software Solutions for Robot Motion

Software Solutions for Robot Motion

Share

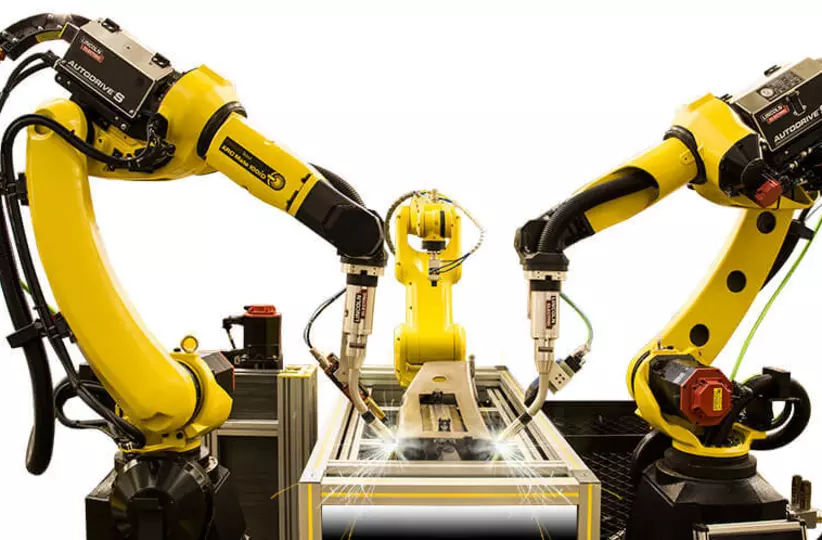

Unlock the full potential of your FANUC robots with our complimentary motion software solutions. From optimising path finding for maximum efficiency to seamlessly coordinating multiple robots, FANUC enables you to design and control complex robot motions with unmatched precision and flexibility.

- Key benefits

- Solutions

- Accessories

Key benefits

Benefits for Your Business

Seamless Integration

Our software seamlessly integrates with your robot systems, ensuring smooth communication and workflow continuity.

Enhanced Precision and Accuracy

Ensure high precision and accuracy in motion control, which is critical for applications requiring exact positioning and smooth movements.

Improved Productivity

Optimise motion control operations, leading to faster cycle times and increased overall productivity. This is essential for you high-volume manufacturing processes.

Solutions

Discover a Selection of FANUC Software Solutions for Motion

Multi-Arm

Enable up to four robots to be simultaneously controlled using a single controller. Utilising DualArm, TripleArm or QuadArm layouts can reduce general operating costs, boost productivity and improve flexibility. They are especially efficient for complex arc welding, material handling and spot welding applications.

Learning Vibration Control (LVC)

Speed up your system. FANUC LVC is the perfect solution for operations that require increased accuracy at high speeds. The FANUC-unique software allows the robot to learn its vibration characteristics by an accelerometer, to optimise its path and to reach higher accelerations while keeping vibration to a minimum, even at maximum speed. For considerably shorter cycle times with highest accuracy – pushing the robot to its limits.

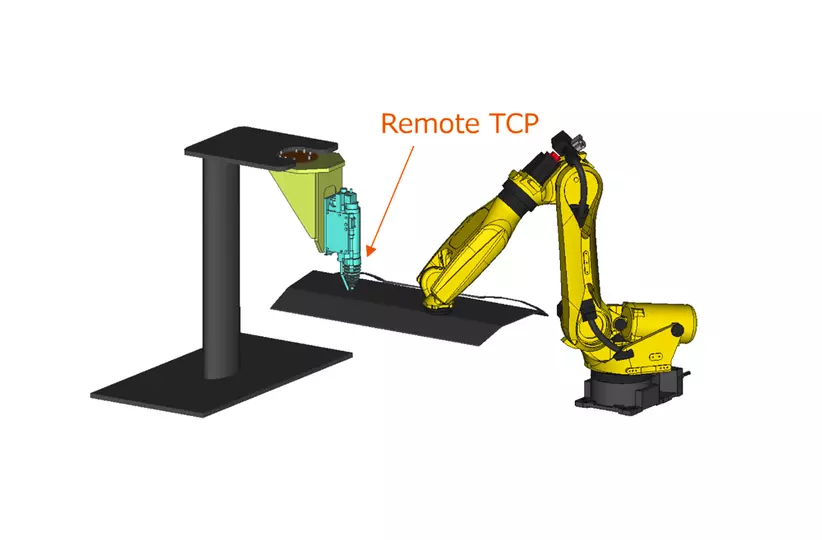

Remote TCP

Move the robot relative to a pedestal tool, simplifying path teaching even with changing workpiece orientation. Ideal for applications like sealant application, it reduces the need for the robot to carry heavy tools, resulting in a more streamlined system and the use of a smaller robot.

Servo Conveyor Line Tracking

Experience the power of FANUC Servo Conveyor Line Tracking. Synchronise your FANUC servo motor with up to four conveyors for precise robot motion tracking. Achieve faster cycle times, improve process stability, increase uptime and reduce system costs compared to conventional solutions.

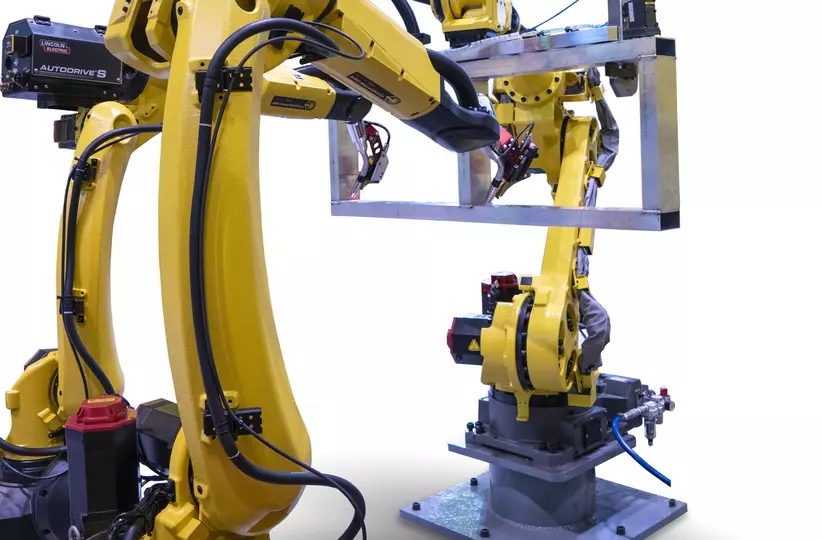

Coordinated Motion

Unleash efficient welding with coordinated motion for your positioner! Reduce programming time by minimising positions and simplify speed control by effortlessly programming relative speeds. Tackle longer, complex weld paths beyond your robot's work envelope. Reposition workpieces for upcoming welds while welding, reducing cycle time. Improve weld quality by harnessing gravity for better penetration and bead formation. Experience faster, more precise, and higher quality welding.

Advance Constant Path

Enhance your robot's efficiency with FANUC's Advanced Path and Speed Control. This software adjusts movement speed by specifying a percentage ratio, ensuring maximum possible speed. It maintains precise control over corner and linear distances, allowing speed changes without altering the taught path. Improve cycle times, achieve optimal speed, and effortlessly teach desired curve paths without trial and error. Experience smoother, faster, and more accurate operations.

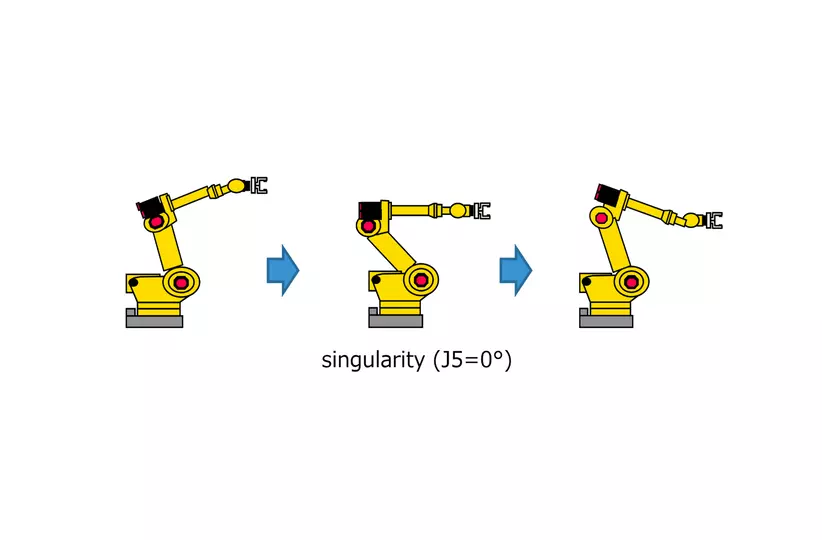

Singularity Avoidance

Allow a 6-axis robot to move smoothly through singularities (J5=0°) in linear motion, allowing operations to be performed close to these points. This feature simplifies your robot programming and increases your operational efficiency by reducing the complexity of paths in areas prone to singularities.

Spline Motion

Enable smooth, continuous robot movement at constant speed through taught points, even with CNT100 termination. You can select the S motion type corresponding to the conventional motion types L, C, and J. Reduce your teaching time by following the target curve precisely. Ideal for applications like roller-hemming, lasers, and dispensing, it ensures accurate path adherence and efficient operation.

Palletising Mode

Allows a 6-axis robot to maintain a constant flange orientation, eliminating J5 singularities. This simplifies tool design and enhances pick-and-place operations. You can easily switch between normal and palletising modes, while jogging in palletising mode streamlines programme teaching for pedestal robots.

Accessories

Discover Suitable Robot Accessories

Servo Positioners

The power to do more - FANUC Servo Positioners open up your options and give you the ability to do more with your FANUC robot. Models cover a range of payloads up to 9000 kg and, depending on your ...

Customised Auxiliary Axes Packages

A fully integrated, standardised and comprehensive auxiliary axis package with FANUC motors is the ideal solution for the most diverse applications that ask for an additional axis to complement you...

Hand Guidance

Our Hand Guidance solutions allow quick and simple programming for your robot by leading it through motion paths. This simple operator control, which requires no further knowledge of the coordinate...

𝑖RPickTool - Advanced Line Tracking

𝑖RPickTool technology takes robotics to a new level of dexterity. By equipping robots with an integrated vision system, it gives them a kind of "eye-hand coordination" similar to humans. This allo...

Get in Touch

Solutions

CUSTOMER SERVICE

NEWS & MEDIA

CONTACT