/

Measurement Functions for Easy Set-Up

Measurement Functions for Easy Set-Up

Share

Reduce complexity and save valuable time with our FANUC Measurement Functions, a suite of built-in tools designed to simplify and expedite the setup process for your CNC machine.

- Insights

- Key Benefits

- Key Features

Insights

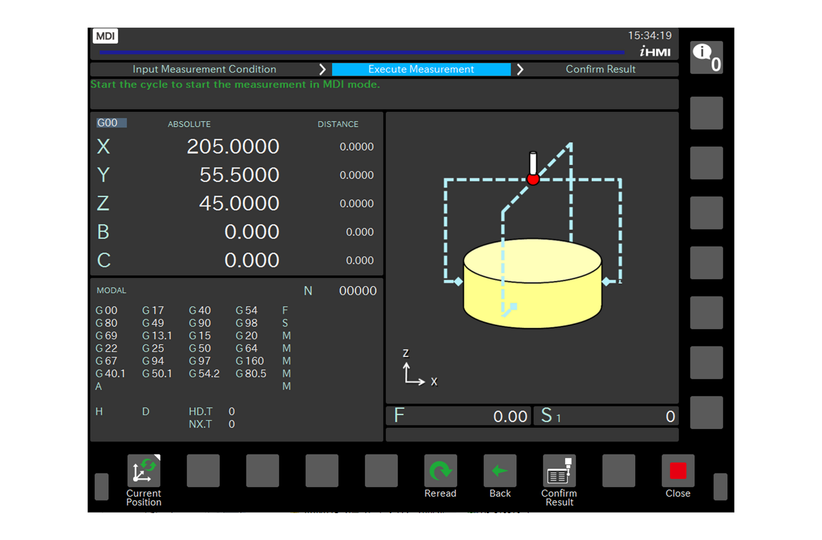

Improve your CNC Setup With Our Measurement Functions

Watch the video to learn more about how it can benefit your business.

Key Benefits

Benefits for Your Business

Effortless Setup

Experience the simplicity of setting up with FANUC CNC Measurement Functions. Our user-friendly interface guarantees a smooth and efficient process, allowing you to maximise your time and resources.

Automated Accuracy

Experience the simplicity of setting up with FANUC CNC Measurement Functions. The technology ensures precise results, enhancing the quality of your output and reducing waste.

Maximised Productivity

Enhance your production efficiency with FANUC CNC Measurement Functions. Our innovative features enable faster processing times, leading to increased production volume and improved profitability.

Reliable Performance

Rely on FANUC CNC Measurement Functions for consistent and reliable performance. Our robust system ensures that your operations run smoothly, maximising uptime and efficiency.

Future-Proof Your Business

Stay ahead of the curve. Our cutting-edge technology is designed to adapt to future advancements, ensuring your business remains competitive in the ever-evolving manufacturing landscape.

Key Features

Features Designed for Your Success

Focus on production, not preparation. Our measurement functions empower you to streamline your CNC setup, minimising downtime and maximising productivity.

Effortless Tool Calibration

Eliminate manual calculations and potential errors with automated tool length and offset measurement.

Simplified Workpiece Setup

Establish precise workpiece positioning using on-machine functions for part zero setting and tool centre point (TCP) measurement.

Enhanced Accuracy and Repeatability

Achieve consistent results and minimise rework with streamlined measurement processes.

Get in Touch

Solutions

CUSTOMER SERVICE

NEWS & MEDIA

CONTACT