Lettner

FANUC IoT System erhöht die Maschinenlaufzeit bei Lettner

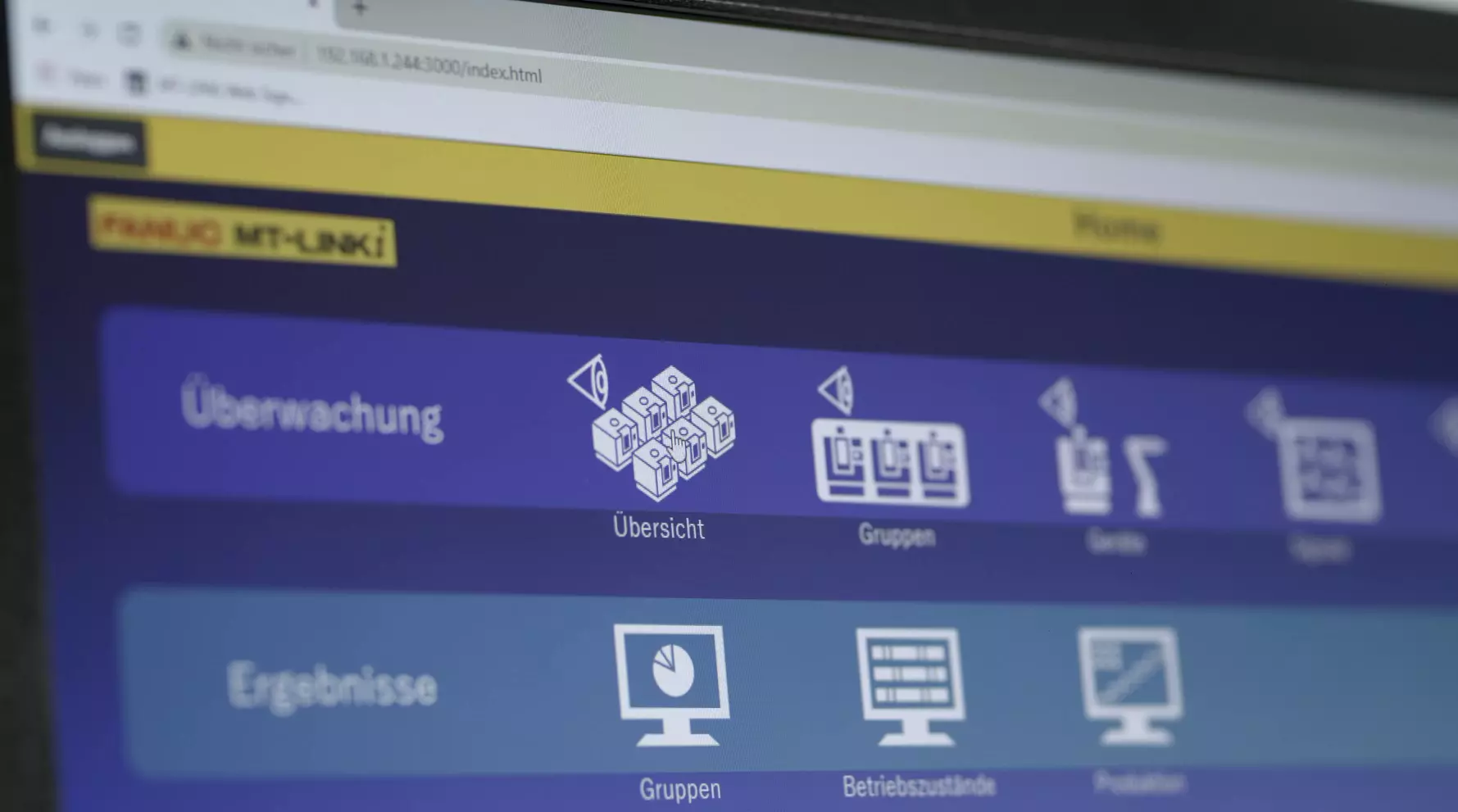

Mit dem Wachstum eines Fertigungsunternehmens wächst auch der Bedarf an einer besseren Produktionsüberwachung und -steuerung. Im digitalen Zeitalter wenden sich immer mehr Unternehmen PC-basierten IoT-Softwaretools zu. Doch welche soll man wählen? Wie Lettner Metallbearbeitung verrät, sprechen viele Argumente für MT-LINK𝑖 von FANUC.

Teilen Sie

FANUC MT-LINK𝑖 zeigt Trends bei Maschinenstillständen auf und hilft zu verstehen, warum diese auftreten.

Die Informationen werden auf jedem PC oder Smartphone angezeigt.

Die IIoT-Lösung von FANUC hat einen positiven Einfluss auf die Produktionszeiten.

Fehlermeldungen während der Geisterschicht erweisen sich als besonders nützlich, um Ausfallzeiten zu reduzieren.

Inspiriert werden

FANUC Fallstudien

Entdecken Sie unser umfassendes Angebot an Fabrikautomatisierungslösungen, die in detaillierten Fallstudien vorgestellt werden und zur Optimierung und Rationalisierung von Fertigungsprozessen entwickelt wurden.

Alle Anwendungen

Von hochpräziser Robotik bis hin zu intelligenter Automatisierung bieten wir die Lösungen, die Ihre Fertigungsprozesse verbessern.

Alle Branchen

Entdecken Sie unser umfassendes Angebot an Lösungen für die Fabrikautomation, die zur Optimierung und Rationalisierung von Fertigungsprozessen entwickelt wurden.